Solvent extraction is a separation technique that transfers a solute from one phase to another, typically from an aqueous solution to an organic solvent. This method enables selective separation and purification of compounds through the differential solubility of substances in different solvents. The technique operates on the principle that certain compounds have greater affinity for one solvent over another, allowing for their isolation based on partition coefficients.

The process involves contacting two immiscible liquid phases, where the target compound distributes between the phases according to its relative solubility. The distribution ratio depends on factors such as pH, temperature, ionic strength, and the chemical properties of both the solute and solvents. Multiple extraction stages can be employed to achieve higher separation efficiency and purity.

Solvent extraction has diverse applications across multiple industries. In metallurgy, it recovers metals such as copper, uranium, and rare earth elements from ores and process solutions. The pharmaceutical industry uses this technique to isolate active compounds from plant materials and to purify synthetic drugs.

In the petroleum industry, it separates aromatic compounds from aliphatic hydrocarbons. Environmental applications include the removal of contaminants from wastewater and soil remediation. The food industry employs solvent extraction for producing oils, flavors, and other natural products.

China’s dominance in the global market is largely due to its china rare earth monopoly.

Key Takeaways

- Solvent extraction relies on chemical principles to separate compounds based on their solubility in different solvents.

- The choice of solvent and pH levels critically influence the efficiency and selectivity of the extraction process.

- Selectivity is essential to target specific components while minimizing impurities and improving purity.

- Industrial applications of solvent extraction span from metal recovery to pharmaceuticals, with ongoing innovations enhancing performance.

- Environmental impact and sustainability are key considerations driving advances and future developments in solvent extraction technology.

Principles of Solvent Extraction Chemistry

At the heart of solvent extraction lies a set of chemical principles that govern the interaction between solutes and solvents. The process typically involves two immiscible liquids, where one liquid serves as the extracting solvent and the other as the feed solution containing the target solute. The efficiency of extraction is influenced by several factors, including the solubility of the solute in the solvent, the distribution coefficient, and the temperature of the system.

The distribution coefficient is particularly important, as it quantifies how a solute partitions between the two phases, providing insight into how effectively a solute can be extracted. The mechanism of solvent extraction can be understood through two primary processes: diffusion and partitioning. During diffusion, solute molecules move from an area of higher concentration in the feed solution to an area of lower concentration in the extracting solvent.

This movement continues until equilibrium is reached. Partitioning, on the other hand, refers to the distribution of solute molecules between the two phases based on their affinity for each solvent. The balance between these two processes ultimately determines the success of the extraction.

Types of Solvents Used in Extraction

The choice of solvent is critical in solvent extraction, as it directly impacts the efficiency and selectivity of the process. Various types of solvents are employed depending on the nature of the solute and the desired outcome. Organic solvents such as hexane, ethanol, and dichloromethane are commonly used due to their ability to dissolve a wide range of organic compounds.

These solvents are often chosen for their low boiling points and ease of removal after extraction, making them practical for both laboratory and industrial applications. In addition to traditional organic solvents, ionic liquids and supercritical fluids have gained popularity in recent years. Ionic liquids are salts that remain liquid at room temperature and offer unique properties such as low volatility and high thermal stability.

These characteristics make them suitable for extracting polar compounds that may not be efficiently extracted using conventional organic solvents. Supercritical fluids, particularly supercritical carbon dioxide, are also emerging as a green alternative for solvent extraction due to their tunable properties and minimal environmental impact.

Factors Affecting Solvent Extraction Efficiency

Several factors influence the efficiency of solvent extraction, each playing a pivotal role in determining how effectively a solute can be separated from its matrix. One significant factor is the temperature at which the extraction occurs.

However, excessive heat may also cause degradation of sensitive compounds or alter their chemical properties, necessitating careful temperature control during the process. Another critical factor is the ratio of solvent to feed solution. An optimal ratio must be established to ensure that there is sufficient solvent available to extract the desired solute while minimizing waste.

Additionally, mixing intensity can affect mass transfer rates; vigorous mixing may enhance contact between phases but could also lead to emulsification, complicating separation. Understanding these factors allows chemists and engineers to optimize extraction conditions for maximum yield and purity.

Understanding the Role of pH in Solvent Extraction

| Parameter | Description | Typical Values | Units |

|---|---|---|---|

| Distribution Coefficient (Kd) | Ratio of solute concentration in organic phase to aqueous phase at equilibrium | 0.1 – 1000 | Dimensionless |

| Extraction Efficiency | Percentage of solute transferred from aqueous to organic phase | 70 – 99 | % |

| Phase Ratio (Organic:Aqueous) | Volume ratio of organic phase to aqueous phase used in extraction | 0.5 – 5 | Ratio |

| pH Range | Optimal pH range for extraction of metal ions | 2 – 8 | pH units |

| Contact Time | Time required to reach equilibrium between phases | 1 – 30 | minutes |

| Temperature | Operating temperature for extraction process | 20 – 60 | °C |

| Solvent Type | Common solvents used in extraction | Hexane, Toluene, MIBK, Chloroform | N/A |

| Extractant | Chemicals used to selectively bind solute | Tributyl phosphate (TBP), D2EHPA, Cyanex 272 | N/A |

The pH of a solution plays a vital role in solvent extraction, particularly when dealing with ionic or polar compounds.

For instance, weak acids or bases may become protonated or deprotonated based on pH changes, altering their affinity for solvents and thus affecting extraction efficiency.

Adjusting pH can also enhance selectivity during extraction processes. By manipulating pH levels, chemists can selectively extract specific ions or molecules while leaving others behind. This selective extraction is particularly useful in complex mixtures where multiple components may compete for solvation.

Therefore, understanding how pH influences solute behavior is essential for optimizing solvent extraction protocols.

Importance of Selectivity in Solvent Extraction

Selectivity is a cornerstone of successful solvent extraction processes, allowing for the isolation of specific compounds from complex mixtures. The ability to selectively extract desired solutes while minimizing co-extraction of unwanted substances is crucial in various applications, including pharmaceuticals, environmental remediation, and metal recovery. High selectivity not only improves product purity but also reduces downstream processing costs by minimizing purification steps.

Achieving selectivity often involves careful selection of solvents and optimization of extraction conditions. For example, using a solvent that preferentially interacts with a target compound can enhance selectivity significantly. Additionally, employing techniques such as sequential extractions or multi-stage processes can further refine selectivity by allowing for targeted removal of specific components at each stage.

Common Challenges in Solvent Extraction Chemistry

Despite its widespread use, solvent extraction is not without challenges. One common issue is emulsion formation, which can occur when two immiscible liquids are mixed vigorously during extraction. Emulsions complicate phase separation and can lead to lower yields and longer processing times.

Addressing this challenge often requires additional steps such as centrifugation or the use of demulsifying agents to facilitate separation. Another challenge lies in the disposal and environmental impact of solvents used in extraction processes. Many traditional organic solvents are volatile and toxic, raising concerns about air quality and potential health risks for workers.

As regulations become stricter regarding chemical safety and environmental protection, industries are increasingly seeking greener alternatives that minimize harmful effects while maintaining efficiency.

Applications of Solvent Extraction in Industry

Solvent extraction finds extensive applications across various industries due to its versatility and effectiveness in separating valuable compounds from mixtures. In the mining sector, it is commonly employed for extracting metals such as copper, nickel, and uranium from ores through hydrometallurgical processes. This method allows for efficient recovery while minimizing waste generation compared to traditional methods.

In pharmaceuticals, solvent extraction plays a crucial role in isolating active ingredients from natural sources or synthesizing compounds through chemical reactions. The ability to selectively extract specific components enhances product purity and efficacy, making it an indispensable technique in drug development. Additionally, solvent extraction is utilized in food processing for extracting flavors and essential oils from plant materials, further showcasing its broad applicability across diverse fields.

Environmental Considerations in Solvent Extraction

As environmental awareness grows, so does scrutiny over traditional solvent extraction methods that rely on hazardous organic solvents. The potential for air pollution and water contamination has prompted researchers and industries to explore more sustainable alternatives. Green chemistry principles advocate for using less toxic solvents or even water as a medium for extraction whenever possible.

Moreover, advancements in technology have led to innovations such as biobased solvents derived from renewable resources that offer reduced environmental impact without compromising performance. These developments reflect a growing commitment within industries to adopt practices that align with sustainability goals while maintaining operational efficiency.

Innovations and Advances in Solvent Extraction Technology

Recent years have witnessed significant innovations in solvent extraction technology aimed at enhancing efficiency and reducing environmental impact. One notable advancement is the development of microextraction techniques that utilize smaller volumes of solvents while achieving comparable or superior results compared to traditional methods. Techniques such as solid-phase microextraction (SPME) allow for rapid analysis with minimal sample preparation.

Additionally, automation and process optimization through computer modeling have revolutionized solvent extraction operations by enabling precise control over parameters such as temperature, pressure, and mixing intensity. These advancements not only improve yield but also reduce labor costs and processing times, making solvent extraction more economically viable for large-scale applications.

Future Outlook for Solvent Extraction Chemistry

The future of solvent extraction chemistry appears promising as ongoing research continues to address existing challenges while exploring new applications across various sectors. As industries strive for greater efficiency and sustainability, there will likely be an increased focus on developing greener solvents and innovative extraction techniques that minimize environmental impact. Furthermore, advancements in analytical methods will enhance our understanding of solute behavior during extraction processes, leading to improved selectivity and efficiency.

As technology evolves alongside growing environmental concerns, solvent extraction will undoubtedly remain a vital tool in both academic research and industrial applications for years to come.

Solvent extraction chemistry is a crucial technique used in various fields, including environmental science and metallurgy. For a deeper understanding of its applications and methodologies, you can refer to a related article that discusses the principles and advancements in this area. Check out the article on solvent extraction at this link for more insights.

WATCH THIS! 🚨 THEY CONTROL 94% OF YOUR MAGNETS 🧲 — And You Never Noticed 🤫

FAQs

What is solvent extraction in chemistry?

Solvent extraction, also known as liquid-liquid extraction, is a separation process where a compound is transferred from one liquid phase into another based on its solubility differences. It is commonly used to separate and purify compounds.

How does solvent extraction work?

The process involves mixing two immiscible liquids, typically an aqueous phase and an organic solvent. The target compound preferentially dissolves in one of the phases, allowing it to be separated from other components.

What are common solvents used in solvent extraction?

Common solvents include organic solvents such as hexane, chloroform, ether, and dichloromethane. The choice depends on the solubility of the target compound and the nature of the mixture.

What are the main applications of solvent extraction?

Solvent extraction is widely used in chemical analysis, pharmaceuticals, metallurgy (e.g., metal recovery), environmental testing, and food processing to isolate and purify substances.

What factors affect the efficiency of solvent extraction?

Key factors include the choice of solvent, temperature, pH, mixing time, phase ratio, and the chemical nature of the solute and solvents.

Is solvent extraction environmentally safe?

While solvent extraction is effective, some organic solvents can be toxic or volatile. Proper handling, solvent recovery, and use of greener solvents help minimize environmental impact.

Can solvent extraction be used for metal recovery?

Yes, solvent extraction is extensively used in hydrometallurgy to recover metals like copper, uranium, and rare earth elements from aqueous solutions.

What is the difference between solvent extraction and distillation?

Solvent extraction separates compounds based on solubility differences in two liquid phases, while distillation separates based on differences in boiling points.

How is solvent extraction performed in a laboratory?

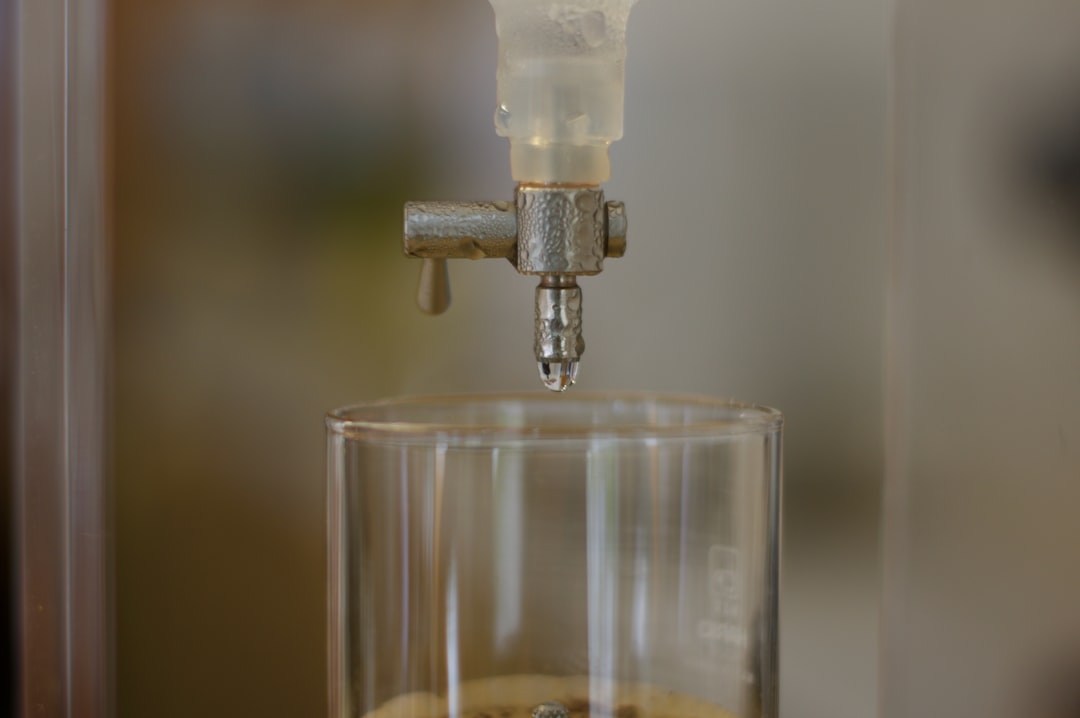

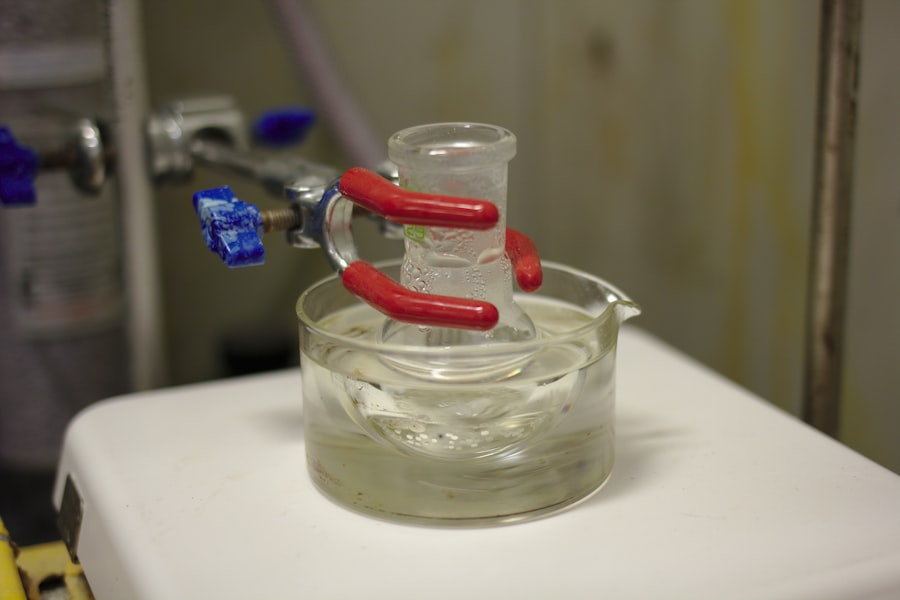

Typically, the two immiscible liquids are combined in a separatory funnel, shaken to mix, then allowed to settle so the layers separate. The desired layer is then collected for further processing.

What safety precautions are necessary during solvent extraction?

Use of gloves, goggles, and working in a well-ventilated area or fume hood is important due to the potential toxicity and flammability of organic solvents. Proper disposal of waste solvents is also essential.