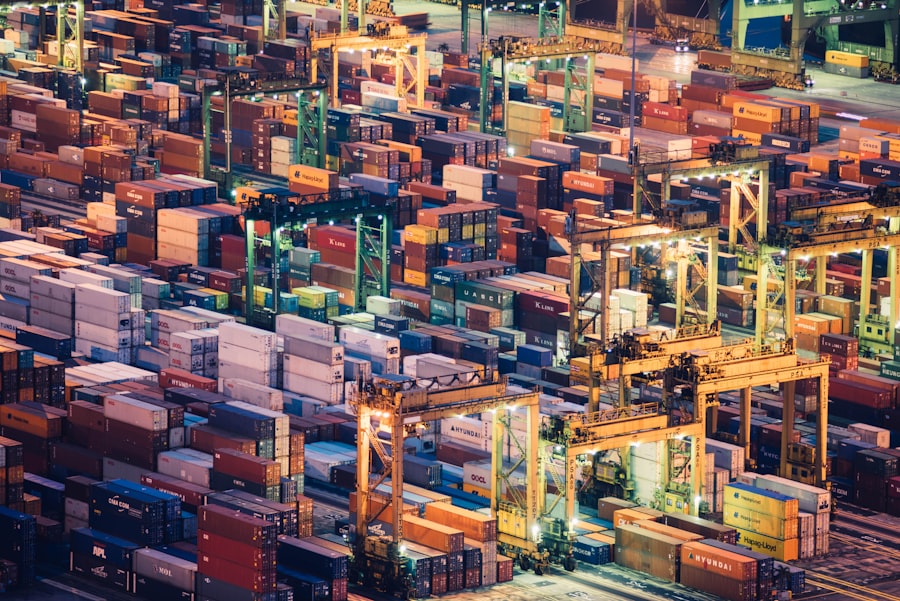

Supply chain disruption has emerged as a critical concern for businesses worldwide, particularly in an era marked by unprecedented global challenges. The intricate web of suppliers, manufacturers, and distributors that form the backbone of modern commerce is increasingly vulnerable to a variety of shocks. These disruptions can stem from natural disasters, geopolitical tensions, pandemics, or even technological failures.

The consequences of these disruptions can ripple through economies, affecting everything from production schedules to consumer prices. Understanding the dynamics of supply chain disruption is essential for businesses aiming to navigate this complex landscape.

Disruptions can lead to delays, increased costs, and a loss of customer trust. As organizations grapple with these challenges, they must also consider the broader implications for their operations and strategic planning. The need for robust supply chain management has never been more pressing, as companies seek to build resilience against future shocks while maintaining competitiveness in an ever-evolving market.

Key Takeaways

- Global events can trigger widespread supply chain disruptions with cascading effects across industries.

- Vulnerable sectors require targeted strategies to mitigate risks and maintain operations.

- Technology plays a crucial role in enhancing supply chain visibility and resilience.

- Building resilient supply chains is essential for navigating future crises effectively.

- Government policies and coordinated responses are key to managing and preventing disruption cascades.

The Impact of Global Events on Supply Chains

Global events have a profound impact on supply chains, often leading to significant disruptions that can alter the course of entire industries. For instance, the COVID-19 pandemic highlighted the vulnerabilities inherent in global supply networks. Lockdowns and restrictions imposed by governments around the world resulted in factory closures and transportation halts, causing delays in production and delivery.

This unprecedented situation forced companies to reevaluate their supply chain strategies and consider alternative sourcing options to mitigate risks. Moreover, geopolitical tensions can also disrupt supply chains in ways that are both immediate and long-lasting. Trade wars, sanctions, and conflicts can lead to sudden changes in tariffs and trade agreements, impacting the flow of goods across borders.

Companies that rely heavily on specific regions for their supplies may find themselves at a disadvantage when political instability arises. The interconnectedness of global markets means that a disruption in one area can have cascading effects on others, underscoring the need for businesses to remain vigilant and adaptable in the face of uncertainty.

The Domino Effect of Supply Chain Disruptions

The domino effect of supply chain disruptions illustrates how interconnected systems can amplify the impact of localized issues. When one link in the supply chain falters, it can trigger a series of failures that extend far beyond the initial problem. For example, if a key supplier experiences a production halt due to a natural disaster, downstream manufacturers may struggle to obtain necessary components, leading to delays in their own production schedules.

This can ultimately result in stock shortages for retailers and dissatisfied customers. The cascading nature of these disruptions highlights the importance of visibility within supply chains. Companies that lack real-time data on their suppliers and logistics may find it challenging to respond effectively to disruptions as they arise.

By understanding the interdependencies within their supply chains, organizations can better anticipate potential risks and develop contingency plans to minimize the impact of disruptions. This proactive approach is essential for maintaining operational continuity and safeguarding customer relationships.

Vulnerable Industries and Sectors

Certain industries are particularly vulnerable to supply chain disruptions due to their reliance on complex networks and just-in-time inventory practices. The automotive sector, for instance, has faced significant challenges in recent years as semiconductor shortages have hampered production. Automakers depend on a steady flow of components from various suppliers, and any disruption in this supply can lead to halted assembly lines and lost revenue.

Similarly, the food and beverage industry is susceptible to disruptions caused by factors such as climate change, labor shortages, and transportation issues. Perishable goods require timely delivery to ensure freshness, making this sector especially sensitive to delays. As consumers increasingly demand transparency regarding sourcing and sustainability, companies within these industries must navigate not only logistical challenges but also evolving consumer expectations.

Strategies for Mitigating Supply Chain Disruptions

| Metric | Description | Example Value | Impact on Supply Chain |

|---|---|---|---|

| Lead Time Increase | Additional time required to receive goods due to disruption | +15 days | Delays production schedules and delivery commitments |

| Inventory Shortfall | Percentage decrease in available stock due to supply interruptions | 30% | Causes stockouts and potential lost sales |

| Supplier Failure Rate | Percentage of suppliers unable to fulfill orders during disruption | 25% | Reduces sourcing options and increases risk |

| Order Backlog | Number of unfulfilled orders accumulated during disruption | 1,200 orders | Increases customer dissatisfaction and operational strain |

| Transportation Delay | Average delay in shipment transit times | +10 days | Impacts delivery reliability and inventory planning |

| Cost Increase | Percentage increase in operational costs due to disruption | 18% | Reduces profit margins and may increase prices |

| Recovery Time | Time required to return to normal supply chain operations | 3 months | Prolonged impact on business continuity |

To mitigate the risks associated with supply chain disruptions, businesses must adopt a multifaceted approach that encompasses risk assessment, diversification, and collaboration. Conducting thorough risk assessments allows organizations to identify potential vulnerabilities within their supply chains and prioritize areas for improvement. By understanding where weaknesses lie, companies can develop targeted strategies to bolster their resilience.

Diversification is another key strategy for mitigating disruptions. Relying on a single supplier or geographic region can expose businesses to significant risks; therefore, establishing relationships with multiple suppliers across different locations can provide a buffer against localized disruptions. Additionally, fostering collaboration among stakeholders within the supply chain can enhance communication and facilitate quicker responses to emerging challenges.

By working together, companies can share insights and resources that contribute to overall supply chain resilience.

The Role of Technology in Addressing Supply Chain Disruptions

Technology plays a pivotal role in addressing supply chain disruptions by enhancing visibility, improving communication, and streamlining operations. Advanced analytics and artificial intelligence enable companies to gain real-time insights into their supply chains, allowing them to identify potential risks before they escalate into major issues. Predictive analytics can help organizations forecast demand fluctuations and adjust their inventory levels accordingly, reducing the likelihood of stockouts or excess inventory.

Moreover, technologies such as blockchain offer enhanced traceability within supply chains, enabling companies to track products from origin to destination. This transparency not only helps organizations respond more effectively to disruptions but also builds trust with consumers who increasingly prioritize ethical sourcing practices. As businesses continue to embrace digital transformation, leveraging technology will be essential for navigating the complexities of modern supply chains.

The Importance of Resilient Supply Chains

Building resilient supply chains is crucial for organizations seeking to thrive in an unpredictable environment. Resilience refers not only to the ability to withstand disruptions but also to recover quickly and adapt to changing circumstances. Companies with resilient supply chains are better positioned to respond effectively to crises, minimizing downtime and maintaining customer satisfaction.

Investing in resilience involves creating flexible supply chain structures that can pivot in response to emerging challenges. This may include adopting agile manufacturing practices or implementing contingency plans that allow for rapid adjustments in sourcing or logistics. By fostering a culture of adaptability within their organizations, businesses can enhance their overall resilience and ensure long-term sustainability in an ever-evolving marketplace.

Government and Policy Responses to Supply Chain Disruptions

Governments play a critical role in addressing supply chain disruptions through policy responses aimed at stabilizing markets and supporting affected industries. During times of crisis, governments may implement measures such as financial assistance programs or regulatory adjustments to facilitate smoother operations for businesses facing challenges. These interventions can help mitigate the immediate impacts of disruptions while laying the groundwork for long-term recovery.

Additionally, international cooperation is essential for addressing global supply chain issues that transcend national borders.

By fostering an environment conducive to trade and investment, policymakers can help create resilient supply chains that are better equipped to withstand future shocks.

The Future of Supply Chain Management in a Post-Crisis World

As businesses emerge from recent crises, the future of supply chain management will likely be characterized by increased emphasis on resilience and adaptability. Organizations will need to rethink traditional approaches to supply chain design and management, prioritizing flexibility over efficiency alone. This shift may involve re-evaluating sourcing strategies, investing in technology solutions, and fostering closer relationships with suppliers.

Furthermore, sustainability will play an increasingly important role in shaping supply chain practices moving forward. Consumers are becoming more conscious of environmental impacts and ethical considerations related to sourcing and production. Companies that prioritize sustainable practices within their supply chains will not only meet consumer expectations but also position themselves as leaders in an evolving marketplace.

Case Studies of Supply Chain Disruption Cascades

Examining case studies of supply chain disruption cascades provides valuable insights into the complexities of these challenges. One notable example is the 2011 earthquake and tsunami in Japan, which had far-reaching effects on global supply chains. The disaster disrupted production at numerous factories, leading to shortages of critical components across various industries, including automotive and electronics.

Companies were forced to reevaluate their reliance on specific regions for sourcing and implement strategies for greater diversification. Another case study involves the recent semiconductor shortage that has impacted multiple sectors worldwide. The pandemic-induced surge in demand for electronics combined with factory shutdowns created a perfect storm for semiconductor manufacturers.

As automakers struggled with production delays due to chip shortages, it became evident how interconnected modern supply chains are and how quickly disruptions can cascade through various industries.

Navigating the Looming Crisis of Supply Chain Disruptions

Navigating the looming crisis of supply chain disruptions requires a proactive approach that prioritizes resilience, adaptability, and collaboration among stakeholders. As global events continue to shape the landscape of commerce, businesses must remain vigilant in identifying potential risks and implementing strategies to mitigate them effectively. By leveraging technology, fostering strong relationships with suppliers, and embracing sustainable practices, organizations can build robust supply chains capable of withstanding future shocks.

Ultimately, the ability to navigate supply chain disruptions will determine not only individual business success but also broader economic stability in an increasingly interconnected world. As companies prepare for an uncertain future, they must recognize that resilience is not merely a response mechanism but a fundamental aspect of strategic planning that will shape their operations for years to come.

Supply chain disruptions can often lead to a cascade of challenges that affect various industries. For a deeper understanding of how these disruptions unfold and their broader implications, you can read a related article on this topic at this link. This article provides insights into the factors contributing to supply chain vulnerabilities and offers strategies for mitigation.

WATCH THIS 🌍 The $3 Trillion Throttle: Who Controls the World’s Supply Chain?

FAQs

What is a supply chain disruption cascade?

A supply chain disruption cascade refers to a series of interconnected disruptions within a supply chain, where an initial disturbance triggers subsequent problems across multiple stages or partners, amplifying the overall impact on the supply chain’s performance.

What causes supply chain disruption cascades?

Common causes include natural disasters, geopolitical events, supplier failures, transportation delays, demand fluctuations, and technological breakdowns. These initial disruptions can propagate through the supply chain, affecting multiple entities.

How do supply chain disruption cascades affect businesses?

They can lead to delays in production, increased costs, inventory shortages, reduced customer satisfaction, and loss of revenue. The cascading effect often magnifies the severity and duration of these impacts.

Can supply chain disruption cascades be predicted?

While it is challenging to predict every disruption, risk assessment tools, data analytics, and supply chain visibility technologies can help identify vulnerabilities and potential cascade effects to some extent.

What strategies help mitigate supply chain disruption cascades?

Strategies include diversifying suppliers, increasing inventory buffers, improving supply chain visibility, implementing flexible logistics, and developing contingency plans to respond quickly to disruptions.

Is technology useful in managing supply chain disruption cascades?

Yes, technologies such as real-time tracking, artificial intelligence, blockchain, and advanced analytics enhance transparency, improve decision-making, and enable faster responses to disruptions.

What industries are most affected by supply chain disruption cascades?

Industries with complex, global supply chains such as automotive, electronics, pharmaceuticals, and retail are particularly vulnerable to disruption cascades.

How does globalization impact supply chain disruption cascades?

Globalization increases supply chain complexity and interdependence, which can amplify the risk and impact of disruption cascades due to longer lead times and multiple cross-border interactions.

What role does communication play in managing supply chain disruption cascades?

Effective communication among supply chain partners is critical for early detection, coordinated response, and minimizing the spread of disruptions throughout the supply chain.

Can supply chain disruption cascades lead to long-term changes in supply chain design?

Yes, significant disruption cascades often prompt companies to redesign their supply chains for greater resilience, including reshoring, nearshoring, and adopting more flexible and transparent supply chain models.