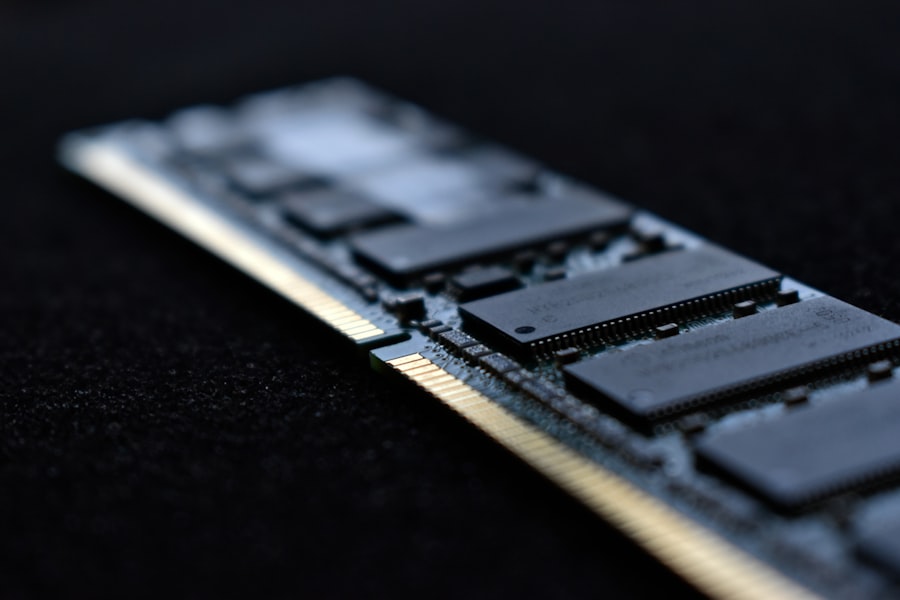

The microchip supply chain is a complex and intricate network that plays a pivotal role in the modern economy. Microchips, or semiconductors, are the backbone of countless electronic devices, from smartphones and computers to automobiles and medical equipment. As technology continues to advance at a rapid pace, the demand for microchips has surged, leading to an increasingly intricate supply chain that encompasses raw material sourcing, manufacturing, assembly, and distribution.

Understanding this supply chain is essential for businesses and consumers alike, as it directly impacts product availability, pricing, and technological innovation. In recent years, the microchip supply chain has garnered significant attention due to its vulnerabilities and the challenges it faces. The COVID-19 pandemic exposed weaknesses in this supply chain, leading to widespread shortages that affected various industries.

As companies strive to adapt to these challenges, it becomes crucial to explore the intricacies of the microchip supply chain, its challenges, and the strategies that can be employed to navigate it effectively. This article aims to provide a comprehensive overview of the microchip supply chain, highlighting its challenges, the impact of global events, and strategies for building resilience and ensuring quality.

Key Takeaways

- The microchip supply chain is a complex network of suppliers, manufacturers, and distributors that play a crucial role in the production and distribution of microchips.

- Global events such as natural disasters, trade disputes, and pandemics can disrupt the microchip supply chain, leading to shortages and delays in production.

- Strategies for navigating the microchip supply chain include diversifying suppliers, implementing risk management plans, and leveraging technology for better visibility and control.

- Building resilience in the microchip supply chain involves fostering strong relationships with suppliers and partners, as well as investing in contingency plans and alternative sourcing options.

- Anticipating and mitigating risks in the microchip supply chain requires proactive monitoring, scenario planning, and continuous improvement to adapt to changing market conditions and technological advancements.

Understanding the Challenges in the Microchip Supply Chain

The microchip supply chain is fraught with challenges that can disrupt production and lead to shortages. One of the primary issues is the reliance on a limited number of manufacturers for semiconductor production. A handful of companies dominate the market, which creates a bottleneck effect.

When demand surges or when one of these manufacturers faces operational difficulties, the entire supply chain can be thrown into disarray. This concentration of production capabilities means that any disruption—be it natural disasters, geopolitical tensions, or even factory accidents—can have far-reaching consequences. Another significant challenge is the complexity of the manufacturing process itself.

Each stage requires specialized equipment and expertise, making it difficult for new entrants to break into the market. Additionally, the process is highly sensitive to variations in materials and environmental conditions.

Any inconsistency can lead to defects in the final product, further complicating supply chain management. As a result, companies must invest heavily in quality control and risk management strategies to mitigate these challenges.

The Impact of Global Events on the Microchip Supply Chain

Global events have a profound impact on the microchip supply chain, often leading to unforeseen disruptions. The COVID-19 pandemic serves as a prime example of how external factors can ripple through this intricate network. Lockdowns and restrictions led to factory closures and reduced workforce availability, causing significant delays in production.

As demand for electronic devices surged during the pandemic—driven by remote work and online learning—the existing supply chain was unable to keep pace, resulting in widespread shortages. Geopolitical tensions also play a critical role in shaping the microchip supply chain landscape. Trade disputes between major economies can lead to tariffs and restrictions that complicate sourcing materials and components.

For instance, tensions between the United States and China have prompted companies to reassess their supply chains and consider diversifying their sources to mitigate risks associated with potential trade barriers. Such geopolitical dynamics underscore the need for companies to remain agile and adaptable in an ever-changing global environment.

Strategies for Navigating the Microchip Supply Chain

| Strategies | Benefits |

|---|---|

| Diversifying suppliers | Reduces dependency on a single supplier |

| Building buffer inventory | Provides a safety net during supply chain disruptions |

| Collaborating with suppliers | Improves communication and visibility in the supply chain |

| Investing in technology | Enhances supply chain visibility and agility |

To effectively navigate the complexities of the microchip supply chain, companies must adopt strategic approaches that enhance their resilience and adaptability. One key strategy is diversification—both in sourcing materials and in manufacturing locations. By spreading their supplier base across different regions and countries, companies can reduce their dependence on any single source and mitigate risks associated with localized disruptions.

This approach not only enhances supply chain stability but also fosters competition among suppliers, potentially leading to better pricing and quality. Another important strategy is investing in advanced forecasting and demand planning tools. Accurate demand forecasting allows companies to anticipate fluctuations in demand and adjust their production schedules accordingly.

By leveraging data analytics and machine learning algorithms, businesses can gain insights into market trends and consumer behavior, enabling them to make informed decisions about inventory management and production capacity. This proactive approach can help prevent shortages and ensure that companies are well-prepared to meet customer demands.

Building Resilience in the Microchip Supply Chain

Building resilience within the microchip supply chain is essential for companies seeking long-term success in an unpredictable environment. One effective way to achieve this is through collaboration with suppliers and partners. Establishing strong relationships with key stakeholders can foster open communication and transparency, allowing companies to respond more effectively to disruptions.

Collaborative efforts can also lead to shared resources and knowledge, enabling companies to innovate and improve their processes collectively. Additionally, investing in technology can significantly enhance resilience within the supply chain. Automation and digitalization can streamline operations, reduce lead times, and improve overall efficiency.

For instance, implementing real-time monitoring systems can provide companies with valuable insights into their supply chain performance, allowing them to identify potential bottlenecks before they escalate into larger issues. By embracing technology as a tool for resilience, companies can better position themselves to adapt to changing market conditions.

The Role of Technology in Managing the Microchip Supply Chain

Technology plays a crucial role in managing the microchip supply chain by enhancing visibility, efficiency, and decision-making capabilities. Advanced technologies such as artificial intelligence (AI), blockchain, and the Internet of Things (IoT) are transforming how companies operate within this complex network. AI-driven analytics can help businesses optimize their inventory levels by predicting demand patterns based on historical data and market trends.

This predictive capability allows companies to make informed decisions about production schedules and resource allocation. Blockchain technology also offers significant potential for improving transparency within the microchip supply chain. By creating a decentralized ledger that records every transaction along the supply chain, companies can enhance traceability and accountability.

This level of transparency not only helps prevent fraud but also enables companies to quickly identify the source of any issues that may arise during production or distribution. As technology continues to evolve, its integration into supply chain management will become increasingly vital for ensuring efficiency and reliability.

Collaborating with Suppliers and Partners in the Microchip Supply Chain

Collaboration with suppliers and partners is essential for navigating the complexities of the microchip supply chain effectively. Establishing strong partnerships fosters trust and open communication, which are critical for addressing challenges as they arise. Companies that prioritize collaboration can benefit from shared knowledge and resources, enabling them to innovate more rapidly and respond effectively to market demands.

Moreover, collaborative relationships can lead to joint problem-solving initiatives that enhance overall supply chain performance. For instance, companies can work together with suppliers to develop contingency plans for potential disruptions or invest in joint research and development projects aimed at improving product quality or reducing costs. By fostering a culture of collaboration within their supply chains, businesses can create a more resilient network capable of adapting to changing circumstances.

Ensuring Quality and Compliance in the Microchip Supply Chain

Ensuring quality and compliance within the microchip supply chain is paramount for maintaining customer trust and meeting regulatory requirements. The production of microchips involves stringent quality control measures at every stage of manufacturing—from raw material sourcing to final testing. Companies must implement robust quality assurance processes that adhere to industry standards while also being flexible enough to adapt to evolving regulations.

Regular audits of suppliers are essential for ensuring compliance with quality standards. By conducting thorough assessments of supplier capabilities and practices, companies can identify potential risks early on and take corrective actions as needed. Additionally, investing in training programs for employees involved in quality control can further enhance compliance efforts by ensuring that staff are well-versed in best practices and industry regulations.

Anticipating and Mitigating Risks in the Microchip Supply Chain

Anticipating and mitigating risks within the microchip supply chain is crucial for maintaining operational continuity. Companies must adopt a proactive approach to risk management by identifying potential vulnerabilities within their supply chains—whether they stem from geopolitical factors, natural disasters, or market fluctuations. Conducting regular risk assessments allows businesses to pinpoint areas of concern and develop strategies for addressing them before they escalate into significant issues.

One effective risk mitigation strategy is developing contingency plans that outline specific actions to be taken in response to various scenarios. These plans should include alternative sourcing options, emergency response protocols, and communication strategies for keeping stakeholders informed during disruptions. By preparing for potential risks in advance, companies can minimize downtime and maintain customer satisfaction even in challenging circumstances.

The Future of the Microchip Supply Chain

The future of the microchip supply chain is poised for transformation as technological advancements continue to reshape industries worldwide. As demand for semiconductors grows across various sectors—including automotive, healthcare, and consumer electronics—companies will need to adapt their supply chains accordingly.

Furthermore, sustainability will play an increasingly important role in shaping the future of the microchip supply chain. As environmental concerns gain prominence globally, companies will be pressured to adopt more sustainable practices throughout their operations—from sourcing materials responsibly to minimizing waste during production processes. Embracing sustainability not only aligns with consumer expectations but also positions companies favorably within an evolving regulatory landscape.

Best Practices for Navigating the Microchip Supply Chain

Navigating the complexities of the microchip supply chain requires a multifaceted approach that encompasses strategic planning, collaboration, technology integration, quality assurance, risk management, and sustainability initiatives. Companies must prioritize diversification in their sourcing strategies while investing in advanced forecasting tools that enable them to anticipate market fluctuations effectively. Building strong relationships with suppliers fosters collaboration that enhances overall supply chain resilience while ensuring compliance with quality standards remains paramount throughout every stage of production.

By adopting best practices such as proactive risk management strategies and embracing technological innovations like AI and blockchain solutions, businesses can position themselves for success in an increasingly competitive landscape. As industries continue to evolve alongside technological advancements, staying ahead of trends will be essential for navigating future challenges within the microchip supply chain effectively. By embracing adaptability as a core principle—alongside a commitment towards sustainability—companies can thrive amidst uncertainty while contributing positively towards shaping a more resilient global economy.

The microchip supply chain has been a topic of significant concern and discussion, especially in light of recent global disruptions. A related article that delves into the intricacies of this issue can be found on MyGeoQuest. This article explores the challenges faced by manufacturers and the innovative solutions being implemented to mitigate these disruptions. For more detailed insights, you can read the full article by visiting