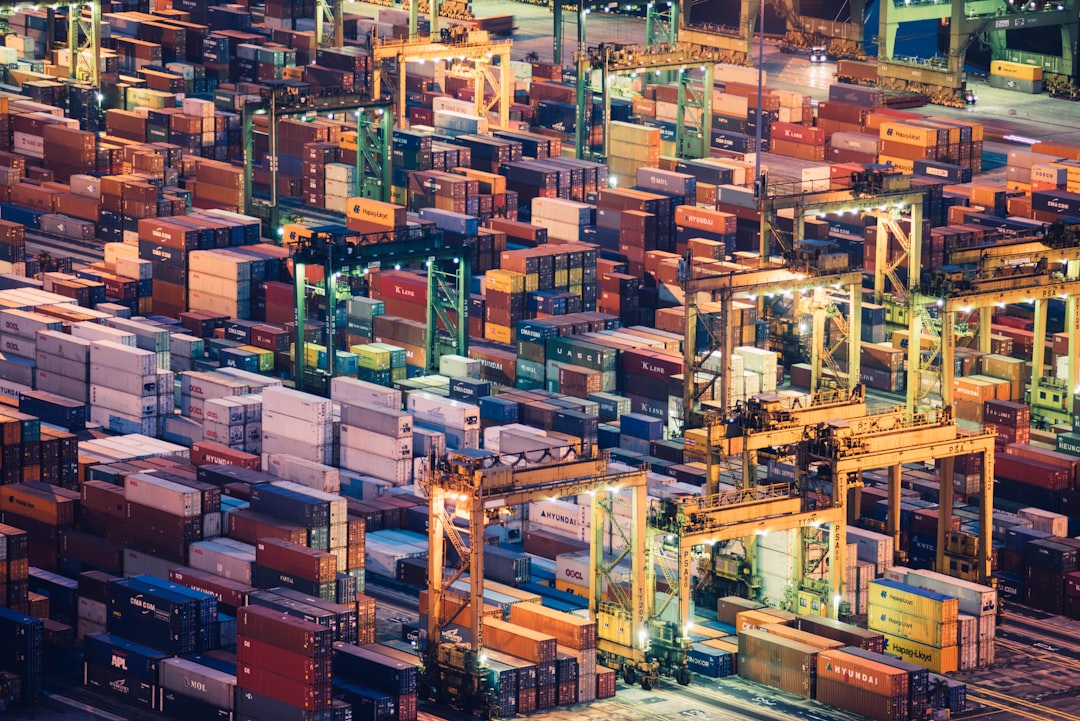

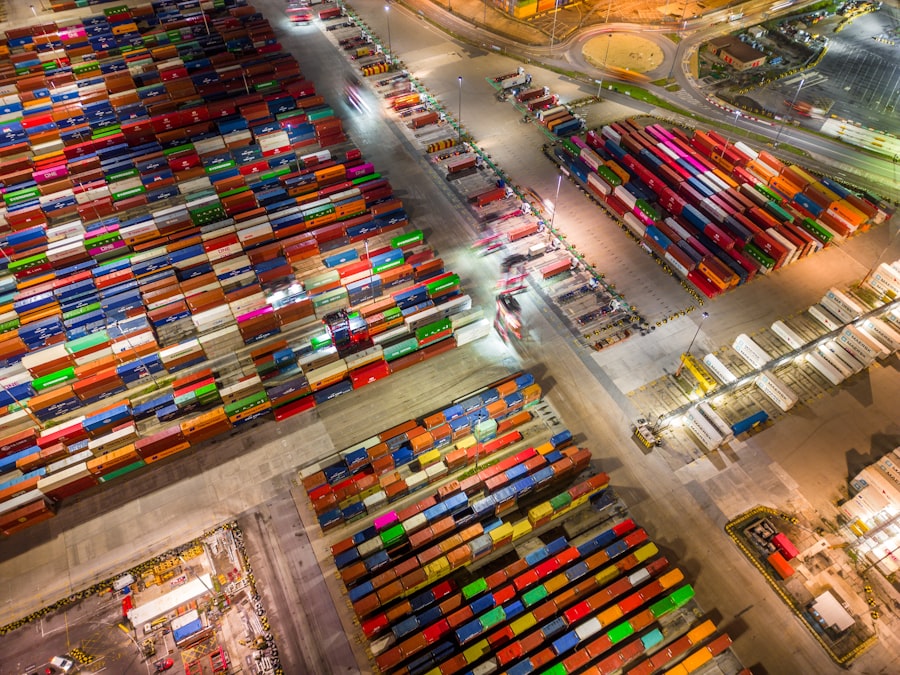

Supply chain chokepoints are critical bottlenecks within supply networks where the movement of goods and services becomes constrained, resulting in delays, increased costs, and operational inefficiencies. These disruptions occur at specific nodes or links in the supply chain where capacity limitations, infrastructure constraints, or external factors create significant impediments to normal flow. Several categories of factors contribute to supply chain chokepoints.

Infrastructure-related bottlenecks include port congestion, limited transportation capacity, and inadequate warehousing facilities. Regulatory factors encompass customs delays, compliance requirements, and trade restrictions. External disruptions such as natural disasters, pandemics, labor strikes, and geopolitical conflicts can also create sudden chokepoints.

Additionally, supplier-related issues including production capacity constraints, quality problems, and financial instability contribute to supply chain vulnerabilities. The globalization of supply chains has amplified both the frequency and impact of chokepoints. Modern supply networks often span multiple countries and involve numerous intermediaries, creating extended chains with multiple potential failure points.

This interconnectedness means that a disruption at one location can cascade through the entire network, affecting multiple tiers of suppliers and customers. Geographic concentration of suppliers or manufacturing in specific regions increases vulnerability to localized disruptions, while just-in-time inventory practices reduce buffer capacity to absorb delays.

Key Takeaways

- Supply chain chokepoints are critical bottlenecks that can disrupt operations and need careful identification and management.

- Effective strategies, including technology adoption and collaboration, are essential to mitigate chokepoint risks.

- Regulatory compliance plays a significant role in managing chokepoints and ensuring smooth supply chain flow.

- Case studies highlight successful approaches to navigating chokepoints and building supply chain resilience.

- Future supply chain management focuses on enhancing resilience and leveraging innovation to address chokepoint challenges.

Identifying Key Chokepoints in the Supply Chain

Identifying key chokepoints within a supply chain requires a comprehensive analysis of the entire operational process. This involves mapping out each stage of the supply chain, from raw material procurement to final product delivery. By visualizing the flow of goods and information, organizations can pinpoint areas where delays are likely to occur.

Common chokepoints include transportation hubs, manufacturing facilities, and distribution centers, where congestion or inefficiencies can lead to significant delays. Moreover, external factors such as weather conditions, political instability, and economic fluctuations can exacerbate these chokepoints. For instance, a natural disaster may disrupt transportation routes, while trade tariffs can create delays in customs clearance.

By continuously monitoring these external influences alongside internal processes, businesses can identify potential chokepoints before they escalate into larger issues. This proactive approach enables organizations to develop contingency plans and allocate resources effectively to mitigate risks. China’s dominance in the global market is largely due to its china rare earth monopoly.

Impact of Chokepoints on Supply Chain Operations

The impact of chokepoints on supply chain operations can be profound and far-reaching. Delays at any stage of the supply chain can lead to increased costs, reduced customer satisfaction, and ultimately, a loss of competitive advantage. For example, if a manufacturing facility experiences a delay in receiving raw materials due to a transportation bottleneck, production schedules may be disrupted, leading to missed deadlines and dissatisfied customers.

This ripple effect can extend throughout the supply chain, affecting not only the organization but also its suppliers and customers. Additionally, chokepoints can strain relationships with stakeholders. Suppliers may become frustrated with inconsistent orders or late payments due to cash flow issues stemming from delays.

Customers may turn to competitors if they perceive that a company cannot deliver products on time. The cumulative effect of these challenges can erode trust and loyalty, making it imperative for organizations to address chokepoints proactively. By understanding the potential consequences of these bottlenecks, businesses can prioritize their efforts to streamline operations and enhance customer satisfaction.

Strategies for Mitigating Chokepoint Risks

To effectively mitigate the risks associated with supply chain chokepoints, organizations must adopt a multifaceted approach that encompasses various strategies. One effective strategy is diversifying suppliers and transportation routes. By not relying on a single source for materials or a specific route for transportation, businesses can reduce their vulnerability to disruptions.

This diversification allows companies to quickly pivot in response to unforeseen challenges, ensuring that operations continue smoothly. Another critical strategy involves investing in inventory management practices that promote flexibility and responsiveness. Implementing just-in-time inventory systems can help organizations maintain optimal stock levels while minimizing excess inventory costs.

Additionally, utilizing safety stock can provide a buffer against unexpected demand spikes or supply disruptions. By balancing inventory levels with demand forecasts, businesses can better navigate potential chokepoints and maintain operational efficiency.

The Role of Technology in Managing Chokepoints

| Chokepoint | Location | Impact on Supply Chain | Average Delay (Days) | Primary Goods Affected | Mitigation Strategies |

|---|---|---|---|---|---|

| Port Congestion | Los Angeles, USA | Delays in container unloading and shipping | 7 | Electronics, Apparel, Automotive Parts | Increase off-peak operations, use alternative ports |

| Rail Network Bottleneck | Chicago, USA | Slowed freight movement across the Midwest | 4 | Industrial Goods, Agricultural Products | Infrastructure upgrades, schedule optimization |

| Customs Clearance Delay | Shanghai, China | Extended processing times for imports/exports | 3 | Consumer Electronics, Machinery | Pre-clearance programs, digital documentation |

| Highway Traffic Congestion | Rotterdam, Netherlands | Slower road freight delivery times | 2 | Food Products, Chemicals | Traffic management, alternative routing |

| Port Labor Shortage | Hamburg, Germany | Reduced cargo handling capacity | 5 | Automotive, Consumer Goods | Automation, workforce training |

Technology plays a pivotal role in managing supply chain chokepoints by providing organizations with the tools needed for real-time monitoring and analysis. Advanced technologies such as artificial intelligence (AI), machine learning, and data analytics enable businesses to gain insights into their supply chain operations. These technologies can identify patterns and trends that may indicate potential chokepoints, allowing organizations to take proactive measures before issues arise.

Moreover, technology facilitates improved communication and collaboration among stakeholders within the supply chain. Cloud-based platforms enable real-time sharing of information between suppliers, manufacturers, and distributors, fostering transparency and accountability. This enhanced communication helps organizations respond more effectively to disruptions and coordinate efforts to mitigate risks associated with chokepoints.

By leveraging technology, businesses can create a more agile and resilient supply chain capable of adapting to changing circumstances.

Collaborative Approaches to Addressing Chokepoints

Collaboration among stakeholders is essential for effectively addressing supply chain chokepoints. By fostering partnerships with suppliers, logistics providers, and other key players in the supply chain, organizations can create a more cohesive network that is better equipped to handle disruptions. Collaborative approaches encourage open communication and information sharing, enabling stakeholders to work together toward common goals.

One effective collaborative strategy is establishing joint contingency planning initiatives. By working together to develop contingency plans for potential disruptions, stakeholders can ensure that everyone is prepared to respond swiftly and effectively when challenges arise. This collaborative mindset not only enhances resilience but also strengthens relationships among partners in the supply chain.

When stakeholders feel invested in each other’s success, they are more likely to prioritize collaboration over competition.

Case Studies of Successful Chokepoint Navigation

Examining case studies of organizations that have successfully navigated supply chain chokepoints provides valuable insights into effective strategies and best practices. For instance, during the COVID-19 pandemic, many companies faced unprecedented disruptions in their supply chains. One notable example is a major automotive manufacturer that quickly adapted its operations by diversifying its supplier base and leveraging technology for real-time monitoring.

By establishing alternative suppliers in different regions, this manufacturer was able to mitigate the impact of factory shutdowns in one area while maintaining production levels elsewhere. Additionally, they implemented advanced analytics tools to monitor inventory levels and demand fluctuations closely. This proactive approach allowed them to respond swiftly to changing market conditions and maintain customer satisfaction despite significant challenges.

Regulatory and Compliance Considerations in Chokepoint Management

Regulatory and compliance considerations play a crucial role in managing supply chain chokepoints effectively. Organizations must navigate a complex landscape of regulations that govern various aspects of their operations, including transportation, customs clearance, and environmental standards. Failure to comply with these regulations can result in delays and additional costs that exacerbate existing chokepoints.

To address these challenges, businesses should stay informed about relevant regulations and engage with legal experts who specialize in supply chain compliance. Regular audits of processes and practices can help identify potential compliance risks before they escalate into significant issues.

The Future of Supply Chain Chokepoint Management

The future of supply chain chokepoint management will likely be shaped by ongoing advancements in technology and evolving market dynamics. As businesses continue to embrace digital transformation, the integration of artificial intelligence and machine learning will become increasingly prevalent in identifying and mitigating chokepoint risks. Predictive analytics will enable organizations to anticipate potential disruptions based on historical data and emerging trends.

Furthermore, sustainability considerations will play an essential role in shaping supply chain strategies moving forward. As consumers become more environmentally conscious, companies will need to prioritize sustainable practices throughout their supply chains. This shift may involve reevaluating sourcing strategies, optimizing transportation routes for reduced carbon emissions, and investing in eco-friendly packaging solutions.

By aligning their operations with sustainability goals, organizations can enhance their resilience against chokepoints while meeting consumer expectations.

Building Resilience in the Supply Chain Against Chokepoints

Building resilience within the supply chain is paramount for organizations seeking to navigate chokepoints effectively. Resilience involves not only the ability to withstand disruptions but also the capacity to adapt and recover quickly when challenges arise. To foster resilience, businesses should focus on developing flexible operational processes that allow for rapid adjustments in response to changing circumstances.

Investing in employee training and development is another critical aspect of building resilience. A well-trained workforce equipped with problem-solving skills can respond more effectively to unexpected challenges within the supply chain. Additionally, fostering a culture of innovation encourages employees to seek out new solutions and approaches that enhance operational efficiency.

By prioritizing resilience as a core value within their organizational culture, businesses can better position themselves to navigate future chokepoint challenges.

Navigating Chokepoints for a Stronger Supply Chain

In conclusion, navigating supply chain chokepoints is essential for organizations striving for operational excellence in an increasingly complex global landscape. By understanding the nature of these bottlenecks and implementing effective strategies for mitigation, businesses can enhance their resilience against disruptions while maintaining customer satisfaction. The integration of technology and collaborative approaches further empowers organizations to address chokepoint challenges proactively.

As companies look toward the future, prioritizing regulatory compliance and sustainability will be crucial for building robust supply chains capable of adapting to evolving market demands. Ultimately, by fostering a culture of resilience and innovation within their operations, organizations can not only navigate existing chokepoints but also emerge stronger in an ever-changing business environment.

In the context of supply chain chokepoint analysis, understanding the geographical factors that influence logistics is crucial. A related article that delves into this topic can be found at this link, where it explores how geographic information systems (GIS) can be utilized to identify and mitigate potential chokepoints in supply chains. This analysis is essential for businesses looking to optimize their operations and enhance efficiency in their supply chain management.

WATCH THIS! 🚨 THEY CONTROL 94% OF YOUR MAGNETS 🧲 — And You Never Noticed 🤫

FAQs

What is supply chain chokepoint analysis?

Supply chain chokepoint analysis is the process of identifying and evaluating critical points within a supply chain where bottlenecks or disruptions are most likely to occur. These chokepoints can impact the flow of goods, materials, or information, potentially causing delays and increased costs.

Why is supply chain chokepoint analysis important?

It is important because it helps organizations anticipate and mitigate risks that could disrupt operations. By understanding chokepoints, companies can improve supply chain resilience, optimize inventory management, and enhance overall efficiency.

What are common types of supply chain chokepoints?

Common chokepoints include limited transportation routes, single-source suppliers, capacity constraints at manufacturing or distribution centers, regulatory delays, and infrastructure limitations such as port congestion.

How is supply chain chokepoint analysis conducted?

The analysis typically involves mapping the entire supply chain, collecting data on processes and capacities, identifying critical nodes, assessing vulnerabilities, and evaluating the potential impact of disruptions at these points.

What tools are used in supply chain chokepoint analysis?

Tools include supply chain mapping software, risk assessment models, simulation and scenario analysis tools, data analytics platforms, and geographic information systems (GIS) to visualize and analyze supply chain networks.

Who benefits from supply chain chokepoint analysis?

Manufacturers, retailers, logistics providers, and supply chain managers benefit by gaining insights that enable proactive risk management, improved planning, and better decision-making.

Can supply chain chokepoint analysis prevent disruptions?

While it cannot completely prevent disruptions, it significantly reduces their likelihood and impact by enabling early identification of vulnerabilities and facilitating contingency planning.

How often should supply chain chokepoint analysis be performed?

It should be conducted regularly, especially when there are changes in suppliers, transportation routes, market conditions, or after experiencing disruptions, to ensure ongoing supply chain resilience.

What role does technology play in supply chain chokepoint analysis?

Technology enhances the accuracy and speed of analysis through real-time data collection, advanced analytics, predictive modeling, and improved visibility across the supply chain network.

Is supply chain chokepoint analysis relevant for all industries?

Yes, all industries with complex supply chains can benefit from chokepoint analysis to manage risks and maintain smooth operations, though the specific chokepoints may vary by sector.