In the realm of electrical engineering, the transformer neutral blocking device plays a pivotal role in ensuring the safe and efficient operation of electrical systems. This device is designed to prevent unwanted current flow through the neutral point of a transformer, which can lead to various operational issues and safety hazards. By effectively blocking the neutral, it helps maintain system stability and protects equipment from potential damage.

The significance of this device cannot be overstated, as it serves as a safeguard against electrical faults that could compromise both the integrity of the transformer and the safety of personnel working in proximity to high-voltage systems. The transformer neutral blocking device is particularly crucial in systems where multiple transformers are interconnected. In such configurations, the neutral point can become a source of circulating currents, which may lead to overheating and eventual failure of the transformers involved.

By implementing a neutral blocking device, engineers can mitigate these risks, ensuring that each transformer operates within its designed parameters. This article will delve into the various aspects of neutral blocking devices, from their importance and installation to maintenance and compliance with industry standards.

Key Takeaways

- Neutral blocking devices are essential for enhancing transformer safety and preventing electrical faults.

- Proper preparation, including gathering the right tools and understanding safety protocols, is crucial before installation.

- A detailed step-by-step installation process ensures correct placement and functionality of the neutral blocking device.

- Regular testing, troubleshooting, and maintenance are necessary to maintain device performance and compliance.

- Adhering to industry regulations and standards is vital for safe and effective transformer neutral blocking device installation.

Understanding the Importance of Neutral Blocking in Transformers

The importance of neutral blocking in transformers extends beyond mere operational efficiency; it encompasses safety, reliability, and longevity of electrical systems. When transformers are connected in parallel or when they share a common neutral point, there is a risk of unbalanced loads leading to excessive neutral currents. These currents can cause overheating, insulation breakdown, and ultimately, transformer failure.

A neutral blocking device acts as a critical line of defense against these issues by preventing the flow of unwanted currents through the neutral point. Moreover, the implementation of a neutral blocking device enhances system reliability by ensuring that each transformer operates independently without interference from others in the network. This independence is vital in maintaining consistent voltage levels and reducing the likelihood of outages caused by faults in one part of the system affecting others.

In essence, neutral blocking devices contribute to a more robust electrical infrastructure, capable of withstanding fluctuations and disturbances while safeguarding both equipment and personnel.

Safety Considerations when Installing a Neutral Blocking Device

Safety is paramount when it comes to installing a neutral blocking device. The installation process involves working with high-voltage equipment, which poses significant risks if not handled correctly. Therefore, it is essential for technicians and engineers to adhere to strict safety protocols throughout the installation process.

This includes wearing appropriate personal protective equipment (PPE), such as insulated gloves, helmets, and safety glasses, to minimize the risk of electrical shock or injury. Additionally, proper training and understanding of electrical systems are crucial for anyone involved in the installation. Technicians should be well-versed in the specific requirements and characteristics of the transformer and its associated components.

This knowledge not only ensures that the installation is performed correctly but also helps in identifying potential hazards that may arise during the process. By prioritizing safety and thorough training, organizations can significantly reduce the risk of accidents and ensure a successful installation of the neutral blocking device.

Steps to Prepare for Installing a Neutral Blocking Device

Preparation is key to a successful installation of a neutral blocking device. The first step involves conducting a thorough assessment of the existing electrical system. This includes reviewing schematics, understanding load requirements, and identifying potential challenges that may arise during installation.

By having a comprehensive understanding of the system’s layout and operational parameters, technicians can devise an effective installation plan that minimizes disruptions. Once the assessment is complete, gathering all necessary documentation is essential. This includes installation manuals for the neutral blocking device itself, as well as any relevant codes or standards that must be adhered to during installation.

Additionally, technicians should prepare a checklist of all required tools and equipment to ensure that everything is on hand when installation begins. This level of preparation not only streamlines the installation process but also helps prevent delays caused by missing components or unforeseen complications.

Tools and Equipment Needed for Installing a Neutral Blocking Device

| Parameter | Specification | Unit | Typical Value | Notes |

|---|---|---|---|---|

| Voltage Rating | Up to 35 kV | kV | 12, 24, 35 | Depends on transformer system voltage |

| Current Rating | Continuous Current | Amps | 200 – 1200 | Based on transformer neutral current |

| Interrupting Capacity | Short Circuit Current | kA | 10 – 25 | Must withstand fault currents |

| Installation Type | Mounting | – | Indoor / Outdoor | Depends on transformer location |

| Operating Temperature Range | -40 to +85 | °C | -40 to +85 | Environmental conditions |

| Neutral Blocking Device Type | Technology | – | Solid State / Electromechanical | Depends on application requirements |

| Response Time | Typical | ms | 5 – 20 | Time to block neutral current |

| Insulation Level | Basic Insulation | kV | 42 / 75 (BIL) | Basic impulse level rating |

| Weight | Approximate | kg | 10 – 50 | Depends on device size and type |

| Maintenance Interval | Recommended | Months | 12 – 24 | Regular inspection and testing |

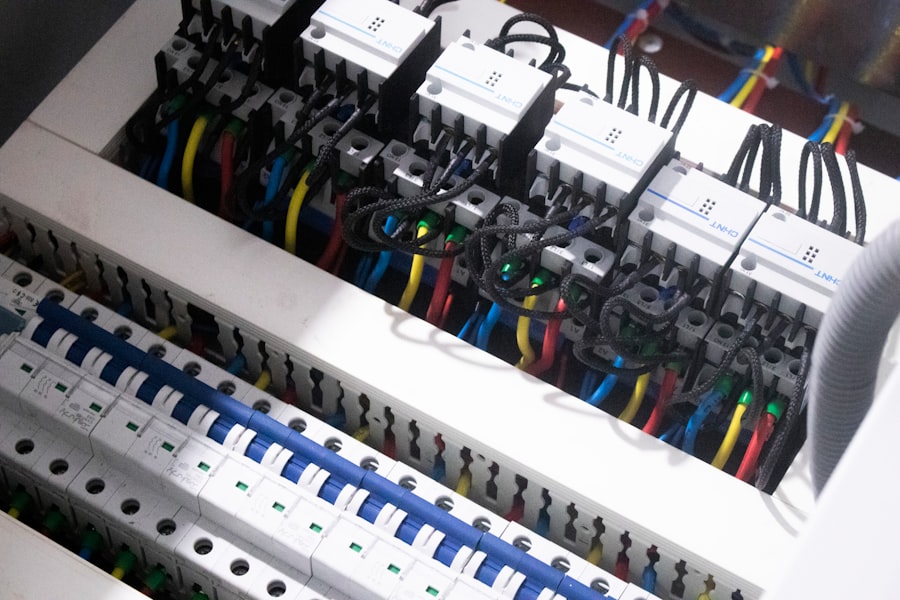

The successful installation of a neutral blocking device requires a specific set of tools and equipment tailored to the task at hand. Essential tools include insulated hand tools such as screwdrivers, pliers, and wrenches designed for high-voltage applications. These tools are crucial for safely handling electrical components without risking accidental contact with live circuits.

In addition to hand tools, technicians will need testing equipment to verify proper functionality before and after installation. This may include multimeters for measuring voltage and current levels, insulation resistance testers to ensure safe operation, and thermal imaging cameras to detect any potential hotspots that could indicate issues with the transformer or its connections. Having these tools readily available not only facilitates a smoother installation process but also enhances overall safety by allowing for thorough testing and verification.

Step-by-Step Guide to Installing a Neutral Blocking Device

The installation process for a neutral blocking device typically follows a systematic approach to ensure accuracy and safety. The first step involves de-energizing the transformer and isolating it from the electrical system. This is critical to prevent any accidental contact with live components during installation.

Once the transformer is safely isolated, technicians can proceed with removing any necessary covers or access panels to gain entry to the internal components. Next, technicians will install the neutral blocking device according to the manufacturer’s specifications. This often involves connecting the device to the transformer’s neutral point while ensuring that all connections are secure and properly insulated.

It is essential to follow any specific guidelines provided in the installation manual to avoid compromising the device’s functionality or safety features. After securing the device in place, technicians will reassemble any covers or panels that were removed during installation. Once everything is back in place, they will conduct thorough testing to verify that the neutral blocking device is functioning correctly before re-energizing the transformer.

This step is crucial for ensuring that all connections are secure and that there are no potential issues that could arise once power is restored.

Testing and Verifying the Functionality of the Neutral Blocking Device

Testing and verification are critical components following the installation of a neutral blocking device. Once power has been restored to the transformer, technicians should conduct a series of tests to ensure that the device is operating as intended. This typically begins with visual inspections to check for any signs of damage or improper connections that may have occurred during installation.

Subsequently, technicians will utilize testing equipment such as multimeters to measure voltage levels at various points within the system. This helps confirm that there are no unexpected currents flowing through the neutral point, indicating that the blocking device is functioning correctly. Additionally, insulation resistance testing should be performed to ensure that all components are adequately insulated and safe for operation.

Once testing is complete and all parameters are within acceptable ranges, technicians can document their findings as part of compliance with industry standards. This documentation serves as an important record for future reference and can be invaluable during routine inspections or audits.

Troubleshooting Common Issues during Installation

Despite careful planning and execution, issues may arise during the installation of a neutral blocking device. One common problem is difficulty in securing connections due to limited space within transformer enclosures. In such cases, technicians may need to employ specialized tools or techniques to reach tight areas without compromising safety or connection integrity.

Another potential issue could be related to compatibility between the neutral blocking device and existing transformer components. If discrepancies arise regarding voltage ratings or connection types, technicians must consult manufacturer specifications or seek guidance from experienced engineers to resolve these conflicts effectively. In instances where unexpected currents are detected during testing after installation, it may indicate improper installation or faulty equipment.

Technicians should revisit their work step-by-step to identify any mistakes made during installation or check for defects in the neutral blocking device itself.

Maintenance and Inspection of the Neutral Blocking Device

Regular maintenance and inspection are essential for ensuring the long-term functionality of a neutral blocking device. Technicians should establish a routine inspection schedule that includes visual checks for signs of wear or damage, as well as functional tests to verify that the device continues to operate effectively over time. During inspections, it is crucial to assess all connections for signs of corrosion or loosening that could compromise performance.

Additionally, technicians should monitor environmental factors such as temperature fluctuations or moisture levels that could impact the integrity of both the transformer and its associated components. Documentation of maintenance activities is also vital for compliance with industry standards and regulations.

Compliance with Regulations and Standards for Neutral Blocking Devices

Compliance with regulations and industry standards is paramount when installing a neutral blocking device. Various organizations set forth guidelines governing electrical installations, including those related specifically to transformers and their components. Adhering to these standards not only ensures safety but also promotes reliability within electrical systems.

Technicians must familiarize themselves with relevant codes such as those established by the National Electrical Code (NEC) or local regulatory bodies governing electrical installations in their region. These codes outline specific requirements regarding materials used, installation practices, testing protocols, and maintenance procedures. By following these regulations diligently throughout every phase—from planning through installation and ongoing maintenance—organizations can mitigate risks associated with non-compliance while enhancing overall system performance.

Conclusion and Final Considerations for Installing a Transformer Neutral Blocking Device

In conclusion, installing a transformer neutral blocking device is an essential undertaking that requires careful planning, execution, and ongoing maintenance. The importance of this device cannot be overstated; it serves as a critical safeguard against unwanted currents that could jeopardize both equipment integrity and personnel safety within electrical systems. By understanding its significance, adhering strictly to safety protocols during installation, preparing adequately with necessary tools and documentation, conducting thorough testing post-installation, troubleshooting potential issues effectively, maintaining regular inspections thereafter—all while ensuring compliance with industry regulations—technicians can ensure optimal performance from their neutral blocking devices over time.

Ultimately, investing time into proper installation practices not only enhances system reliability but also contributes positively towards creating safer working environments within electrical engineering fields across various industries worldwide.

When considering the installation of a transformer neutral blocking device, it’s essential to understand the various factors that can influence its effectiveness and safety. For a comprehensive overview of the installation process and best practices, you can refer to the article on transformer installations available at this link. This resource provides valuable insights that can help ensure a successful implementation of your neutral blocking device.

FAQs

What is a transformer neutral blocking device?

A transformer neutral blocking device is an electrical component installed in the neutral connection of a transformer to prevent unwanted current flow, such as zero-sequence or ground fault currents, from passing through the neutral point.

Why is a neutral blocking device installed on a transformer?

It is installed to improve system protection, reduce circulating currents, minimize neutral point voltage fluctuations, and prevent damage to the transformer and connected equipment caused by ground faults or unbalanced loads.

Where is the neutral blocking device installed on a transformer?

The device is typically installed in the neutral conductor of the transformer winding, often at the neutral terminal or neutral grounding point, depending on the system design and grounding method.

What types of neutral blocking devices are commonly used?

Common types include neutral blocking reactors (inductors), neutral blocking capacitors, and neutral blocking filters, each designed to block or limit specific types of currents in the neutral path.

Is special equipment required for installing a neutral blocking device?

Yes, installation usually requires appropriate tools for electrical connections, safety equipment, and sometimes specialized testing instruments to verify correct installation and operation.

Can a neutral blocking device be installed on any transformer?

While it can be installed on many transformers, the decision depends on the transformer’s grounding method, system requirements, and protection scheme. It is typically used in systems with solidly grounded or impedance-grounded neutrals.

What safety precautions should be taken during installation?

Ensure the transformer and associated circuits are de-energized and properly grounded, follow lockout/tagout procedures, use personal protective equipment, and adhere to relevant electrical codes and standards.

How does a neutral blocking device affect transformer performance?

When properly installed, it helps stabilize the neutral point voltage, reduces fault currents, and enhances system reliability without negatively impacting normal transformer operation.

Is maintenance required for neutral blocking devices?

Yes, periodic inspection and testing are recommended to ensure the device remains functional and effective, including checking connections and verifying electrical parameters.

Who should perform the installation of a transformer neutral blocking device?

Qualified electrical engineers or technicians with experience in power systems and transformer installations should perform the installation to ensure safety and compliance with standards.