Dysprosium and terbium are rare earth elements (REEs) essential to numerous modern technologies. Dysprosium (atomic number 66) is a silvery-white metal characterized by high reactivity and distinctive magnetic properties. Terbium (atomic number 65) exhibits green luminescence and functions as a performance enhancer in various materials.

Both elements belong to the lanthanide series and occur naturally together in minerals including xenotime and monazite. These elements serve critical functions in high-technology applications spanning electric vehicles and renewable energy systems. Their unique properties make them indispensable for manufacturing advanced materials that enable technological innovation.

The global transition toward sustainable energy solutions is driving increased demand for dysprosium and terbium, establishing their strategic importance in international markets.

Key Takeaways

- Dysprosium and terbium are critical rare earth elements with unique magnetic and luminescent properties.

- These elements are essential for advanced technologies like electric vehicles, wind turbines, and electronics.

- Mining and processing of dysprosium and terbium involve complex extraction and refining methods with environmental concerns.

- Market demand for these elements is rising, driven by green energy and high-tech industries, but supply challenges persist.

- Innovations in processing aim to improve efficiency and reduce environmental impact, shaping a promising future for rare earth element utilization.

Importance of Rare Earth Elements

Rare earth elements, including dysprosium and terbium, are crucial for numerous industries due to their unique physical and chemical properties. These elements are vital in the production of high-strength magnets, phosphors, catalysts, and various electronic devices. The growing reliance on technology in everyday life has made REEs indispensable, particularly in sectors such as electronics, renewable energy, and defense.

For instance, dysprosium is a key component in the manufacturing of neodymium-iron-boron magnets, which are used in wind turbines and electric motors. Moreover, the importance of rare earth elements extends to national security. Many countries recognize that access to these materials is essential for maintaining technological superiority and economic stability.

As a result, governments are increasingly investing in research and development to secure supply chains for these critical resources. The geopolitical implications of rare earth element availability cannot be overstated, as nations vie for control over mining operations and processing facilities. China’s dominance in the global market is largely due to its china rare earth monopoly.

Mining and Extraction of Dysprosium and Terbium

The mining and extraction of dysprosium and terbium present unique challenges due to their scarcity and the complexity of their geological deposits. These elements are typically extracted from ores that contain a mixture of rare earth elements, necessitating sophisticated mining techniques. The most common methods include open-pit mining and underground mining, depending on the depth and location of the deposits.

Once extracted, the ores undergo a series of processes to separate dysprosium and terbium from other elements. The extraction process often involves crushing the ore and using chemical methods to isolate the desired elements. This can include solvent extraction or ion exchange techniques, which selectively separate dysprosium and terbium from other rare earths.

However, the mining process itself can be environmentally damaging, leading to concerns about land degradation and pollution. As such, there is a growing emphasis on developing more sustainable mining practices that minimize environmental impact while ensuring a steady supply of these critical materials.

Processing and Refining Techniques

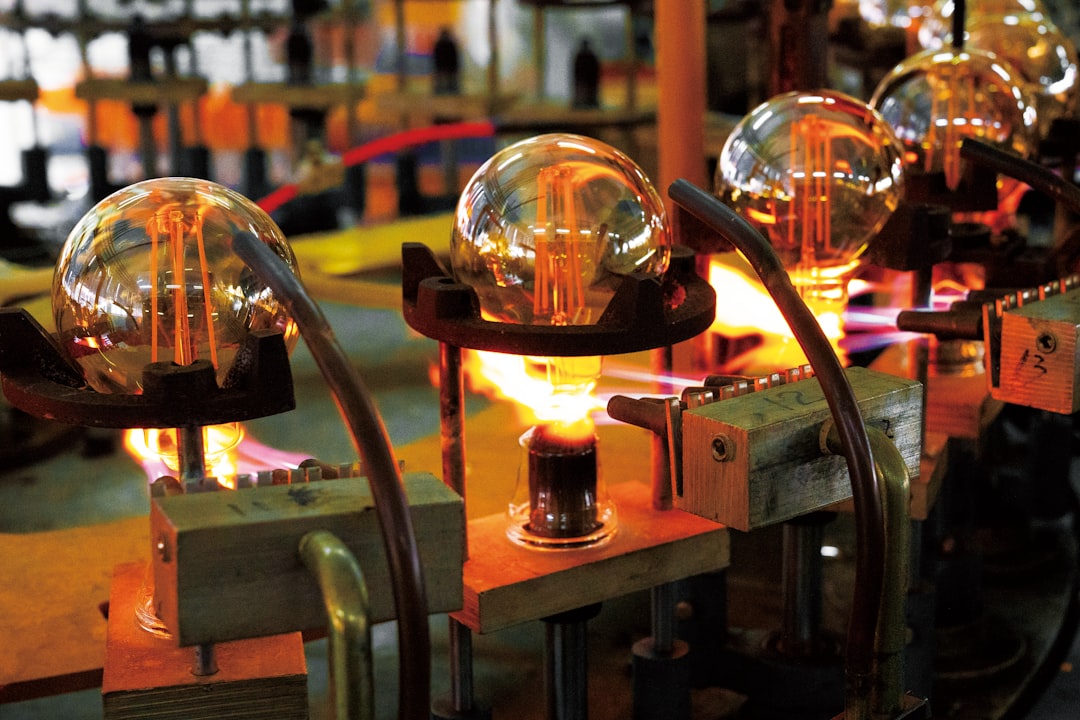

Once dysprosium and terbium have been extracted from their ores, they must undergo processing and refining to achieve the desired purity levels for industrial applications. The refining process typically involves several stages, including leaching, precipitation, and calcination. During leaching, acids or other solvents are used to dissolve the rare earth elements from the ore, creating a solution that can be further processed.

Following leaching, the solution undergoes precipitation to separate dysprosium and terbium from other impurities. This step is crucial for achieving high purity levels necessary for applications in electronics and other high-tech industries. Finally, calcination is employed to convert the precipitated compounds into oxides or metals through high-temperature treatment.

Applications of Dysprosium and Terbium

| Metric | Dysprosium | Terbium | Notes |

|---|---|---|---|

| Atomic Number | 66 | 65 | Lanthanide series elements |

| Typical Ore Source | Monazite, Bastnäsite | Monazite, Bastnäsite | Often co-extracted from same ores |

| Extraction Method | Solvent extraction, Ion exchange | Solvent extraction, Ion exchange | Separation challenging due to similar properties |

| Purity Level Achieved | 99.9% | 99.9% | High purity required for magnet applications |

| Processing Temperature | 600-800°C (for reduction) | 600-800°C (for reduction) | Used in metallothermic reduction |

| Yield Efficiency | 85-90% | 80-85% | Depends on ore quality and process |

| Common Applications | Permanent magnets, lasers | Phosphors, permanent magnets | Both critical for high-performance magnets |

Dysprosium and terbium find applications across a wide range of industries due to their unique properties. Dysprosium is particularly valued for its ability to enhance the performance of permanent magnets, making it essential in electric vehicles (EVs), wind turbines, and various electronic devices. The demand for high-performance magnets has surged with the rise of green technologies, positioning dysprosium as a critical component in achieving energy efficiency.

Terbium’s applications are equally diverse; it is commonly used in phosphors for lighting and display technologies. The element’s luminescent properties make it ideal for producing green light in LED displays and fluorescent lamps. Additionally, terbium is utilized in various alloys to improve their strength and thermal stability.

As technology continues to evolve, the potential applications for dysprosium and terbium are likely to expand further, driving innovation across multiple sectors.

Environmental Impact of Rare Earth Element Processing

The processing of rare earth elements like dysprosium and terbium raises significant environmental concerns that cannot be overlooked. The extraction and refining processes often generate hazardous waste materials that can contaminate soil and water sources if not managed properly. Additionally, the use of toxic chemicals during processing poses risks to both human health and local ecosystems.

Efforts are being made to mitigate these environmental impacts through improved waste management practices and the development of greener extraction methods. For instance, researchers are exploring bioleaching techniques that utilize microorganisms to extract rare earth elements more sustainably. By adopting such innovative approaches, the industry aims to reduce its ecological footprint while still meeting the growing demand for these essential materials.

Market Trends and Demand for Dysprosium and Terbium

The market for dysprosium and terbium has experienced fluctuations in recent years due to changing demand dynamics driven by technological advancements.

Analysts predict that this trend will continue as more countries commit to reducing carbon emissions and transitioning towards sustainable energy sources.

Conversely, terbium’s market has also seen growth but at a different pace. The demand for high-quality phosphors in display technologies has contributed to its steady market presence. However, supply chain disruptions caused by geopolitical tensions have raised concerns about availability, prompting companies to seek alternative sources or develop substitutes for these rare earth elements.

Overall, understanding market trends is crucial for stakeholders looking to navigate the complexities of the rare earth element landscape.

Challenges in Dysprosium and Terbium Processing

Processing dysprosium and terbium presents several challenges that industry players must address to ensure efficient production. One significant hurdle is the complexity of separating these elements from other rare earths during refining processes. Given their similar chemical properties, achieving high purity levels can be labor-intensive and costly.

Additionally, fluctuations in global supply chains can impact processing operations. Geopolitical tensions or trade restrictions may lead to shortages or increased prices for raw materials needed in processing. Companies must remain agile in their strategies to adapt to these challenges while maintaining production efficiency.

Investing in research and development can help overcome some of these obstacles by improving existing processing techniques or discovering new methods altogether.

Innovations in Dysprosium and Terbium Processing

Innovation plays a pivotal role in enhancing the efficiency of dysprosium and terbium processing techniques. Researchers are actively exploring new methods that could streamline extraction and refining processes while minimizing environmental impact. For instance, advancements in hydrometallurgy have shown promise in improving separation techniques through more selective chemical reactions.

Moreover, there is a growing interest in recycling rare earth elements from electronic waste as a sustainable alternative to traditional mining practices. By recovering dysprosium and terbium from discarded devices, companies can reduce reliance on primary sources while addressing waste management issues. Such innovations not only contribute to resource conservation but also align with global sustainability goals.

Future Outlook for Rare Earth Elements

The future outlook for dysprosium and terbium appears promising as global demand for rare earth elements continues to rise. With increasing investments in clean energy technologies and electric vehicles, these elements will likely play an even more significant role in shaping future innovations. As industries strive for greater efficiency and sustainability, dysprosium’s magnetic properties and terbium’s luminescent capabilities will remain indispensable.

However, challenges such as supply chain vulnerabilities and environmental concerns must be addressed proactively to ensure a stable future for these critical materials. Collaborative efforts among governments, industries, and researchers will be essential in developing sustainable practices that support long-term growth while safeguarding ecological integrity.

Harnessing the Potential of Dysprosium and Terbium

In conclusion, dysprosium and terbium represent vital components of modern technology with far-reaching implications across various industries. Their unique properties make them indispensable in applications ranging from renewable energy solutions to advanced electronics. As demand continues to grow, it is crucial for stakeholders to harness their potential responsibly while addressing environmental concerns associated with mining and processing.

By investing in innovative techniques and sustainable practices, the industry can ensure a steady supply of these rare earth elements while minimizing ecological impact. The future of dysprosium and terbium is bright; with continued research and collaboration, they will undoubtedly play a pivotal role in driving technological advancements that benefit society as a whole.

Dysprosium and terbium are critical rare earth elements used in various high-tech applications, and their processing is essential for the advancement of modern technologies. For a deeper understanding of the methods and challenges involved in the processing of these elements, you can refer to a related article on this topic at My Geo Quest. This resource provides valuable insights into the extraction and refinement processes that are crucial for harnessing the potential of dysprosium and terbium in various industries.

WATCH THIS! 🚨 THEY CONTROL 94% OF YOUR MAGNETS 🧲 — And You Never Noticed 🤫

FAQs

What is dysprosium terbium processing?

Dysprosium terbium processing refers to the methods and techniques used to extract, separate, and purify the rare earth elements dysprosium (Dy) and terbium (Tb) from their ores or recycled materials. These processes are essential for producing high-purity metals used in various industrial applications.

Why are dysprosium and terbium important?

Dysprosium and terbium are critical rare earth elements used primarily in manufacturing permanent magnets, phosphors, and other advanced materials. Dysprosium enhances the heat resistance and magnetic strength of neodymium magnets, while terbium is used in green phosphors for lighting and display technologies.

What are the common sources of dysprosium and terbium?

Dysprosium and terbium are typically found together in rare earth mineral deposits such as monazite, bastnäsite, and xenotime. They can also be recovered from recycled electronic waste and industrial byproducts.

What are the main steps involved in processing dysprosium and terbium?

The processing generally involves mining the ore, crushing and grinding, followed by physical and chemical separation techniques such as flotation, solvent extraction, ion exchange, and precipitation to isolate and purify dysprosium and terbium.

What challenges are associated with dysprosium terbium processing?

Challenges include the complexity of separating these elements due to their similar chemical properties, environmental concerns related to mining and chemical processing, and the need for efficient recycling methods to reduce dependency on primary sources.

How is environmental impact managed during processing?

Environmental management includes using cleaner extraction technologies, recycling waste materials, treating effluents to remove harmful chemicals, and adhering to regulations to minimize pollution and ecological damage.

Are there any alternatives to dysprosium and terbium in industrial applications?

Research is ongoing to find alternative materials or reduce the amount of dysprosium and terbium used in magnets and phosphors. However, currently, these elements remain critical due to their unique properties.

What industries rely on dysprosium and terbium?

Key industries include electronics, renewable energy (wind turbines), automotive (electric vehicles), lighting, and defense sectors, all of which utilize the magnetic and luminescent properties of these rare earth elements.