The magnet manufacturing industry plays a pivotal role in various sectors, including electronics, automotive, renewable energy, and healthcare. Magnets are essential components in countless applications, from electric motors and generators to magnetic resonance imaging (MRI) machines.

This industry is characterized by a diverse range of products, including permanent magnets, electromagnets, and magnetic assemblies, each serving unique functions across different applications. In recent years, the magnet manufacturing sector has witnessed significant transformations driven by technological advancements, globalization, and evolving consumer preferences. The industry’s landscape is increasingly shaped by consolidation, as larger companies acquire smaller firms to enhance their capabilities and market reach.

This article delves into the historical context of magnet manufacturing, the factors driving consolidation, key players in the market, and the implications of these changes for competition and innovation.

Key Takeaways

- The magnet manufacturing industry has experienced significant consolidation driven by technological innovation and market competition.

- Key players dominate the market, influencing pricing, production, and global trade dynamics.

- Technological advancements are critical for maintaining competitiveness and fostering innovation within the industry.

- Regulatory and environmental factors increasingly impact manufacturing processes and industry standards.

- Small and medium-sized enterprises face challenges but also opportunities in adapting to globalization and evolving market trends.

Historical Overview of Magnet Manufacturing

The history of magnet manufacturing can be traced back to ancient civilizations that utilized naturally occurring magnets, such as lodestone, for navigation and other purposes. However, it was not until the 19th century that significant advancements were made in the understanding and production of artificial magnets. The development of electromagnets in the early 1800s marked a turning point, enabling the creation of stronger and more versatile magnetic materials.

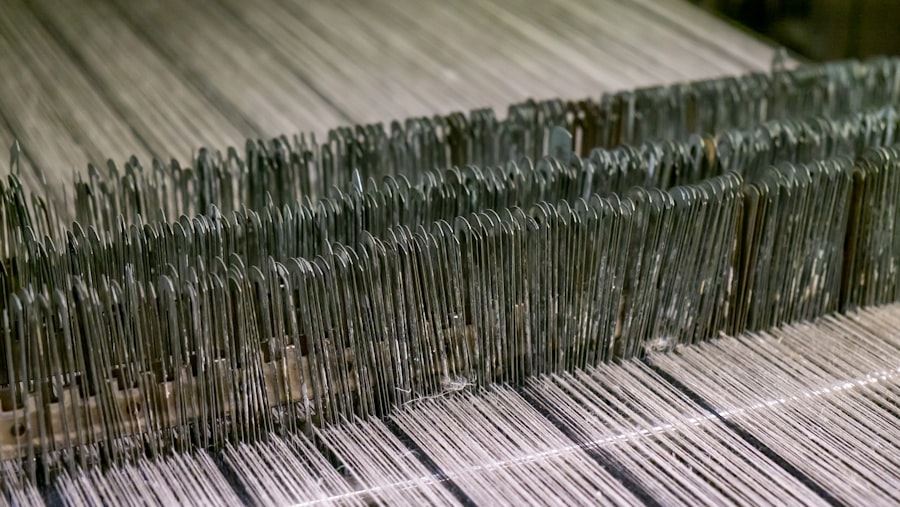

This innovation laid the groundwork for the modern magnet manufacturing industry. Throughout the 20th century, the demand for magnets grew exponentially with the rise of electrical engineering and the proliferation of electronic devices. The introduction of new materials, such as ferrites and rare-earth elements, revolutionized magnet production by enhancing performance characteristics like strength and durability.

As industries expanded and diversified, manufacturers began to specialize in various types of magnets, leading to a more segmented market. The latter part of the century saw the emergence of global supply chains, allowing manufacturers to source raw materials and components from different regions, further shaping the industry’s evolution. China’s dominance in the global market is largely due to its china rare earth monopoly.

Factors Driving Consolidation in the Industry

Several factors contribute to the ongoing consolidation within the magnet manufacturing industry. One primary driver is the need for economies of scale. As competition intensifies and profit margins narrow, larger companies seek to reduce costs by consolidating operations and streamlining production processes.

By acquiring smaller firms, they can leverage existing resources and expertise to enhance efficiency and reduce overhead expenses. Another significant factor is the increasing complexity of technology in magnet applications. As industries demand more sophisticated magnetic solutions, manufacturers must invest heavily in research and development to stay competitive.

Consolidation allows companies to pool resources and share knowledge, fostering innovation and accelerating product development cycles. Additionally, larger firms often have greater access to capital, enabling them to invest in cutting-edge technologies that smaller companies may struggle to afford.

Key Players in the Magnet Manufacturing Industry

The magnet manufacturing industry is home to several key players that dominate the market landscape. Companies such as Hitachi Metals, Neodymium Magnet Co., and Arnold Magnetic Technologies are recognized for their extensive product offerings and technological expertise. These firms have established themselves as leaders by consistently delivering high-quality magnets that meet stringent industry standards.

In addition to these established players, there are numerous smaller manufacturers that contribute to the industry’s diversity. These companies often focus on niche markets or specialized applications, allowing them to carve out a unique position within the broader landscape. The interplay between large corporations and smaller enterprises fosters a dynamic environment where innovation thrives, driving advancements in magnet technology and applications.

Impact of Consolidation on Market Competition

| Year | Number of Magnet Manufacturers | Market Share of Top 5 Companies (%) | Global Production Volume (tons) | Average Production Cost per kg | Major Mergers & Acquisitions |

|---|---|---|---|---|---|

| 2018 | 120 | 45 | 15,000 | 35 | Company A acquired Company B |

| 2019 | 110 | 50 | 16,500 | 33 | Company C merged with Company D |

| 2020 | 95 | 58 | 18,000 | 30 | Company E acquired Company F |

| 2021 | 80 | 65 | 20,000 | 28 | Company G merged with Company H |

| 2022 | 70 | 70 | 22,500 | 27 | Company I acquired Company J |

The consolidation trend within the magnet manufacturing industry has profound implications for market competition. On one hand, it can lead to increased efficiency and innovation as larger firms leverage their resources to develop new products and technologies. This can benefit consumers by providing access to higher-quality magnets at competitive prices.

However, consolidation also raises concerns about reduced competition and potential monopolistic practices. As larger companies acquire smaller competitors, there is a risk that market diversity may diminish. This could result in fewer choices for consumers and potentially stifle innovation as dominant players may prioritize their interests over those of smaller firms.

Regulatory bodies may need to monitor these developments closely to ensure that competition remains healthy and that consumers continue to benefit from a vibrant marketplace.

Technological Advancements and Innovation in Magnet Manufacturing

Technological advancements have been a driving force behind the evolution of magnet manufacturing. Innovations in materials science have led to the development of high-performance magnets with superior strength-to-weight ratios and enhanced thermal stability. For instance, rare-earth magnets, such as neodymium-iron-boron (NdFeB), have revolutionized various applications due to their exceptional magnetic properties.

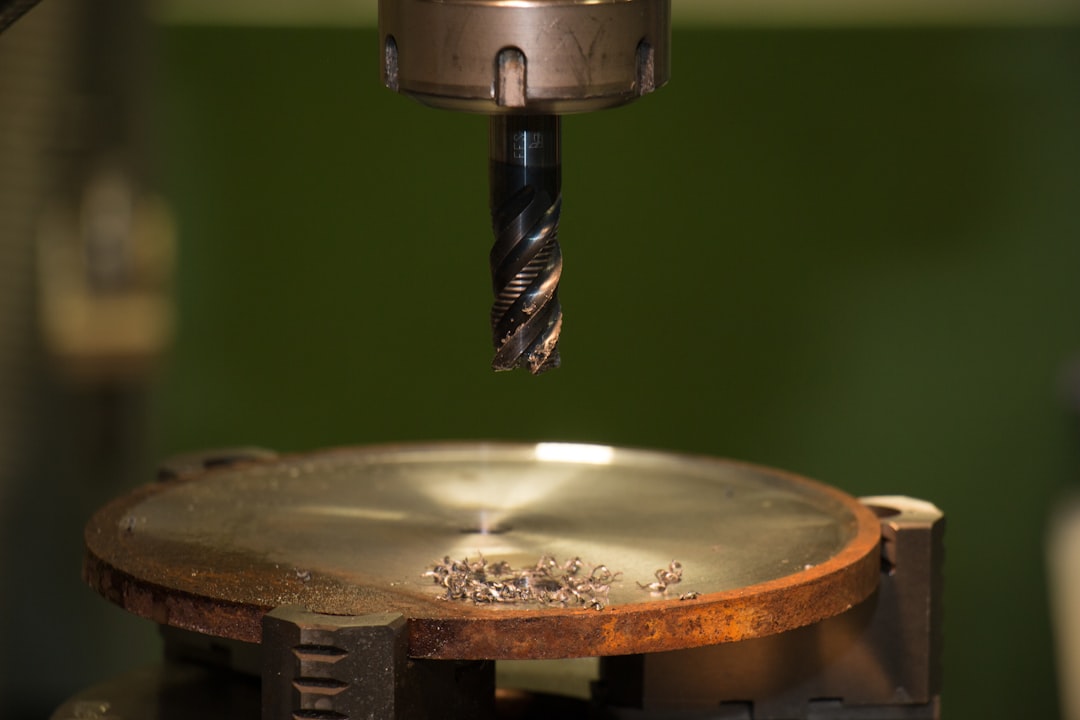

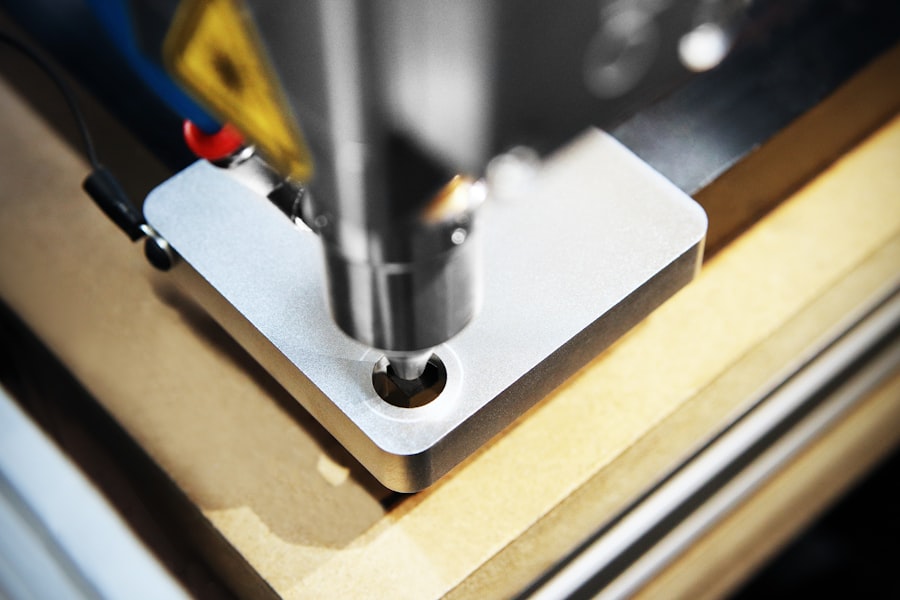

Moreover, advancements in manufacturing processes have enabled greater precision and efficiency in magnet production. Techniques such as additive manufacturing and advanced sintering methods allow for the creation of complex geometries and customized magnetic solutions tailored to specific applications. As industries continue to demand more sophisticated magnetic technologies, manufacturers are compelled to invest in research and development to stay at the forefront of innovation.

Regulatory and Environmental Considerations in Magnet Manufacturing

The magnet manufacturing industry is subject to various regulatory frameworks aimed at ensuring product safety and environmental sustainability. Manufacturers must comply with standards set by organizations such as the International Organization for Standardization (ISO) and adhere to regulations governing hazardous materials used in production processes. This includes managing substances like rare-earth elements, which can pose environmental risks if not handled properly.

In recent years, there has been a growing emphasis on sustainability within the industry. Companies are increasingly adopting eco-friendly practices in their manufacturing processes, such as recycling materials and reducing waste. Additionally, consumers are becoming more conscious of environmental impacts, prompting manufacturers to prioritize sustainable sourcing and production methods.

As regulatory pressures mount and consumer preferences shift towards greener alternatives, companies that embrace sustainability are likely to gain a competitive edge.

Challenges and Opportunities for Small and Medium-sized Enterprises

Small and medium-sized enterprises (SMEs) face unique challenges within the magnet manufacturing industry amid ongoing consolidation trends. Limited resources can hinder their ability to compete with larger firms that benefit from economies of scale and extensive R&D budgets. Additionally, SMEs may struggle to access global supply chains or secure contracts with major clients due to their size.

However, these challenges also present opportunities for SMEs to differentiate themselves through specialization and innovation. By focusing on niche markets or developing customized solutions for specific applications, smaller manufacturers can carve out a loyal customer base. Furthermore, collaboration with larger firms or participation in industry partnerships can provide SMEs with access to resources and expertise that enhance their competitiveness.

Globalization and International Trade in Magnet Manufacturing

Globalization has significantly influenced the magnet manufacturing industry by facilitating international trade and expanding market reach. Manufacturers can source raw materials from various regions while accessing diverse markets for their products. This interconnectedness has led to increased competition but also presents opportunities for collaboration across borders.

Countries rich in rare-earth resources, such as China, play a crucial role in the global supply chain for magnet manufacturing. However, geopolitical tensions and trade policies can impact supply chains and pricing dynamics within the industry. As manufacturers navigate these complexities, they must remain agile and adaptable to changing market conditions while exploring new avenues for growth in emerging markets.

Future Trends and Projections for the Magnet Manufacturing Industry

Looking ahead, several trends are poised to shape the future of the magnet manufacturing industry. The increasing demand for electric vehicles (EVs) is expected to drive growth in high-performance magnets used in motors and batteries. As governments worldwide push for greener transportation solutions, manufacturers will need to innovate continuously to meet evolving requirements.

Additionally, advancements in renewable energy technologies will create new opportunities for magnet manufacturers. Wind turbines and solar energy systems rely heavily on efficient magnetic components for optimal performance. As these industries expand, so too will the demand for specialized magnets designed for renewable energy applications.

Strategies for Success in a Consolidated Magnet Manufacturing Market

In a consolidated magnet manufacturing market, companies must adopt strategic approaches to thrive amidst competition. Fostering innovation through continuous research and development is essential for staying ahead of technological advancements. Collaborating with academic institutions or industry partners can enhance R&D efforts while providing access to cutting-edge knowledge.

Moreover, focusing on customer relationships is crucial for building loyalty in a competitive landscape. Understanding client needs and providing tailored solutions can differentiate manufacturers from their competitors. Emphasizing sustainability practices can also resonate with environmentally conscious consumers, positioning companies favorably within the market.

In conclusion, the magnet manufacturing industry is undergoing significant changes driven by consolidation trends, technological advancements, regulatory considerations, and globalization dynamics. While challenges exist for small and medium-sized enterprises amidst this evolving landscape, opportunities abound for those willing to innovate and adapt strategically.

The recent trends in magnet manufacturing consolidation have raised significant discussions in the industry, particularly regarding the implications for supply chains and innovation. For a deeper understanding of these dynamics, you can read the related article on this topic at this link. This article explores the factors driving consolidation and its potential impact on the market landscape.

WATCH THIS! 🚨 THEY CONTROL 94% OF YOUR MAGNETS 🧲 — And You Never Noticed 🤫

FAQs

What is magnet manufacturing consolidation?

Magnet manufacturing consolidation refers to the process where multiple companies in the magnet production industry merge or are acquired to form larger entities. This often aims to improve efficiency, reduce costs, and increase market share.

Why is consolidation happening in the magnet manufacturing industry?

Consolidation occurs due to factors such as increasing competition, the need for technological advancements, cost pressures, and the desire to expand product portfolios and geographic reach.

How does consolidation affect the magnet manufacturing market?

Consolidation can lead to fewer but larger companies dominating the market, potentially resulting in improved innovation, streamlined operations, and better resource allocation. However, it may also reduce competition.

What types of magnets are typically involved in manufacturing consolidation?

Consolidation can involve various types of magnets, including rare earth magnets (like neodymium and samarium-cobalt), ferrite magnets, and alnico magnets, depending on the companies involved.

Who are the major players in the magnet manufacturing industry?

Major players often include multinational corporations specializing in magnetic materials and components. Specific company names vary over time due to mergers and acquisitions.

What are the benefits of magnet manufacturing consolidation for customers?

Customers may benefit from improved product quality, broader product offerings, enhanced research and development capabilities, and potentially more competitive pricing.

Are there any risks associated with magnet manufacturing consolidation?

Risks include reduced competition leading to higher prices, potential job losses, and less diversity in product innovation.

How does consolidation impact innovation in magnet manufacturing?

Consolidation can both positively and negatively impact innovation; larger companies may have more resources for R&D, but reduced competition might decrease the incentive to innovate.

What role do technological advancements play in magnet manufacturing consolidation?

Technological advancements often drive consolidation as companies seek to combine expertise and resources to develop new magnetic materials and manufacturing processes.

How can smaller magnet manufacturers compete in a consolidated market?

Smaller manufacturers may focus on niche markets, specialized products, or customized solutions to differentiate themselves from larger consolidated entities.