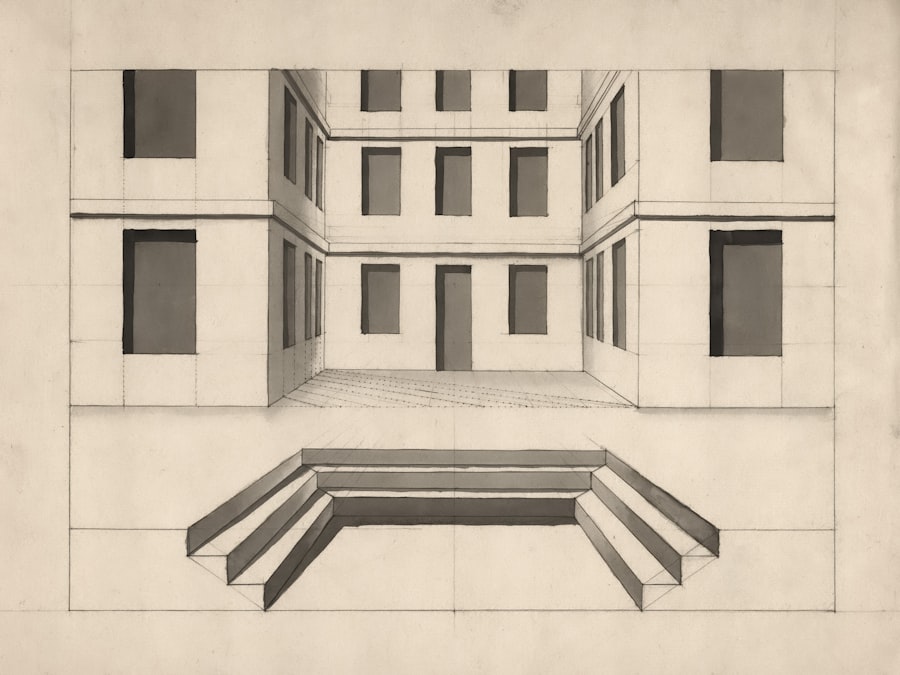

As-built drawings serve as a critical component in the construction and engineering industries, providing a detailed representation of a project as it has been completed. These drawings capture the final specifications, dimensions, and locations of all elements within a structure, reflecting any changes made during the construction process. Their importance cannot be overstated, as they serve as a definitive record that can be referenced for future renovations, maintenance, or expansions.

By documenting the actual conditions of a project, as-built drawings ensure that all stakeholders have a clear understanding of what has been constructed, which is essential for effective communication and project management. Moreover, as-built drawings play a vital role in regulatory compliance and safety assessments. They provide essential information for inspections and audits, ensuring that the completed work adheres to local building codes and regulations.

In the event of disputes or claims, these drawings can serve as legal evidence to clarify what was built versus what was originally planned. Thus, the accuracy and completeness of as-built drawings are paramount, as they not only reflect the physical reality of a project but also safeguard the interests of all parties involved.

Key Takeaways

- As-built drawings are crucial for accurately documenting the final state of construction projects.

- Discrepancies between as-built drawings and real-life conditions are common and can impact project outcomes.

- Technology, such as 3D scanning and BIM, plays a key role in identifying and addressing these discrepancies.

- Regular comparison and updating of as-built drawings help prevent legal issues and improve project management.

- Implementing best practices and embracing innovations ensures more accurate and reliable as-built documentation.

Understanding the Discrepancies Between As-Built Drawings and Real Life

Discrepancies between as-built drawings and the actual conditions on-site are not uncommon in construction projects. These differences can arise from various factors, including design changes made during construction, unforeseen site conditions, or errors in the original plans. Understanding these discrepancies is crucial for project managers, architects, and engineers, as they can significantly impact the overall success of a project.

Recognizing the reasons behind these differences allows professionals to address them proactively rather than reactively. Furthermore, discrepancies can lead to confusion among team members and stakeholders if not properly documented and communicated. When as-built drawings do not accurately reflect the constructed environment, it can result in misinterpretations that may affect future work or maintenance.

Therefore, it is essential for construction teams to establish a clear process for updating as-built drawings throughout the project lifecycle. This ongoing documentation helps ensure that all changes are captured in real-time, minimizing the potential for discrepancies and enhancing overall project clarity.

Common Differences Between As-Built Drawings and Real Life

Several common differences can be observed between as-built drawings and the actual conditions on-site. One prevalent issue is related to dimensional discrepancies. During construction, measurements may be altered due to site constraints or material availability, leading to variations from the original design.

For instance, if a wall is shifted slightly to accommodate existing utilities or if structural elements are modified for better load distribution, these changes may not be reflected in the as-built drawings unless meticulously documented. Another frequent discrepancy involves the installation of systems such as plumbing, electrical wiring, and HVAC components. These systems often require adjustments during installation due to unforeseen obstacles or changes in design intent.

As a result, the locations of pipes, ducts, and conduits may differ from what is indicated in the original plans. If these modifications are not accurately recorded in the as-built drawings, it can create challenges for future maintenance or renovations, as workers may struggle to locate essential systems within walls or ceilings.

The Impact of Discrepancies on Construction Projects

| Metric | Description | Impact on Construction Projects | Typical Range |

|---|---|---|---|

| Discrepancy Rate | Percentage of drawings or documents containing errors or inconsistencies | Higher rates lead to increased rework and delays | 5% – 20% |

| Rework Time | Additional hours spent correcting discrepancies | Extends project schedule and increases labor costs | 10% – 30% of total project time |

| Cost Overrun | Additional expenses incurred due to discrepancies | Raises overall project budget beyond initial estimates | 5% – 15% of total project cost |

| Project Delay | Time extension caused by resolving discrepancies | Delays project completion and affects stakeholder satisfaction | 2 – 8 weeks |

| Change Orders | Number of formal modifications issued to address discrepancies | Increases administrative workload and project complexity | 3 – 10 per project |

| Quality Defects | Number of defects arising from unresolved discrepancies | Impacts structural integrity and safety | 1 – 5 defects per 1000 sq. ft. |

The impact of discrepancies between as-built drawings and real-life conditions can be profound and multifaceted.

When discrepancies are discovered after construction is complete, it may necessitate costly rework or modifications to address issues that could have been avoided with accurate documentation.

This not only affects the budget but can also lead to delays in project timelines as teams scramble to rectify problems. Additionally, discrepancies can compromise safety and functionality. If critical systems are installed incorrectly or if structural elements do not align with safety standards due to undocumented changes, it can pose risks to occupants and users of the building.

In extreme cases, this could lead to structural failures or safety incidents that could have been prevented with accurate as-built documentation. Therefore, addressing discrepancies promptly is essential to ensure that projects meet safety standards and function as intended.

The Role of Technology in Comparing As-Built Drawings to Real Life

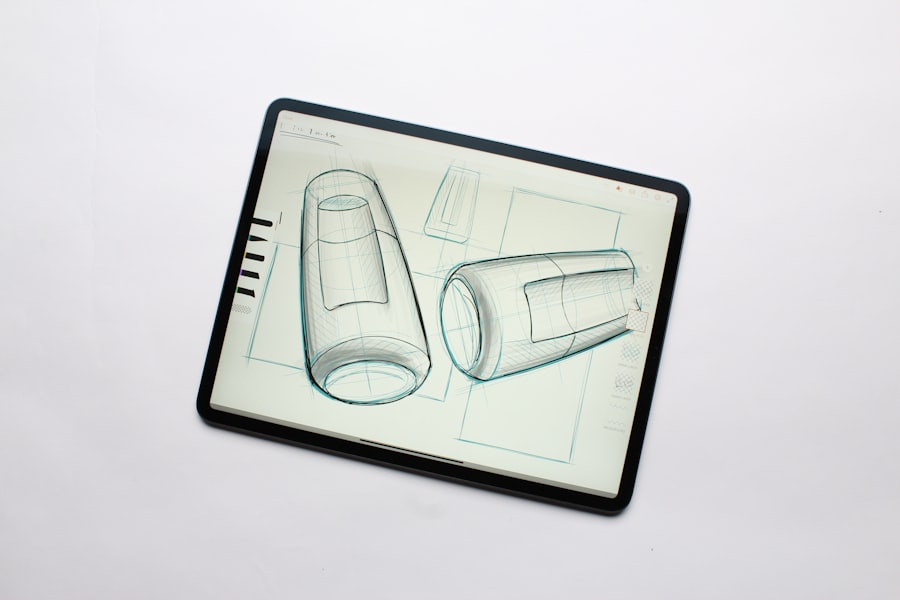

In recent years, technology has played an increasingly vital role in comparing as-built drawings to real-life conditions on construction sites. Advanced tools such as Building Information Modeling (BIM), laser scanning, and drones have revolutionized how professionals capture and analyze data related to construction projects. BIM allows for the creation of detailed 3D models that can be updated in real-time, providing an accurate representation of both design intent and actual construction progress.

Laser scanning technology enables teams to capture precise measurements of existing conditions quickly. By comparing these scans with as-built drawings, discrepancies can be identified with remarkable accuracy. Drones further enhance this process by providing aerial views of large construction sites, allowing for comprehensive assessments of progress and alignment with design specifications.

The integration of these technologies not only streamlines the comparison process but also enhances collaboration among team members by providing a shared visual reference.

Strategies for Addressing Discrepancies

To effectively address discrepancies between as-built drawings and real-life conditions, several strategies can be employed throughout the construction process. First and foremost is the implementation of regular site inspections and updates to as-built documentation. By conducting frequent reviews of the work completed against the original plans, teams can identify any deviations early on and make necessary adjustments to their documentation.

Another effective strategy involves fostering open communication among all stakeholders involved in a project. Encouraging collaboration between architects, engineers, contractors, and subcontractors ensures that everyone is aware of any changes made during construction.

Case Studies: Real-Life Examples of Discrepancies

Examining real-life case studies can provide valuable insights into how discrepancies between as-built drawings and actual conditions have impacted construction projects. One notable example involved a large commercial building where significant deviations were discovered during final inspections. The original plans indicated specific locations for electrical conduits; however, due to unforeseen site conditions, these conduits were installed in different locations without proper documentation.

This oversight led to delays in obtaining occupancy permits and required costly rework to bring the building up to code. Another case involved a residential development where discrepancies in grading levels resulted in drainage issues after construction was completed. The as-built drawings did not accurately reflect the final grading due to changes made during excavation.

As a result, water pooled in certain areas of the property, leading to complaints from homeowners and necessitating additional landscaping work to rectify the situation. These examples underscore the importance of maintaining accurate as-built documentation throughout the construction process.

The Legal Implications of Discrepancies

Discrepancies between as-built drawings and actual conditions can also have significant legal implications for construction projects. In cases where disputes arise regarding project completion or compliance with contractual obligations, accurate as-built documentation becomes crucial evidence in legal proceedings. If discrepancies are not properly documented or communicated, it may lead to claims of negligence or breach of contract.

Furthermore, failure to address discrepancies can result in liability issues if safety concerns arise from undocumented changes. For instance, if a building’s structural integrity is compromised due to unrecorded modifications, affected parties may seek legal recourse against contractors or architects involved in the project. Therefore, maintaining accurate records and addressing discrepancies promptly is essential not only for project success but also for protecting against potential legal ramifications.

The Benefits of Regularly Comparing As-Built Drawings to Real Life

Regularly comparing as-built drawings to real-life conditions offers numerous benefits that extend beyond mere accuracy. One significant advantage is enhanced project efficiency. By identifying discrepancies early on through ongoing comparisons, teams can address issues before they escalate into larger problems that require extensive rework or delays.

This proactive approach ultimately leads to smoother project execution and improved timelines. Additionally, regular comparisons foster better communication among team members and stakeholders. When discrepancies are documented and discussed openly, it creates an environment where everyone is informed about changes made during construction.

This transparency helps build trust among team members and ensures that all parties are aligned on project goals and expectations.

Best Practices for Creating Accurate As-Built Drawings

Creating accurate as-built drawings requires adherence to best practices throughout the construction process. One fundamental practice is establishing a clear protocol for documenting changes as they occur on-site. This includes assigning responsibility for updating drawings to specific team members who are present during construction activities.

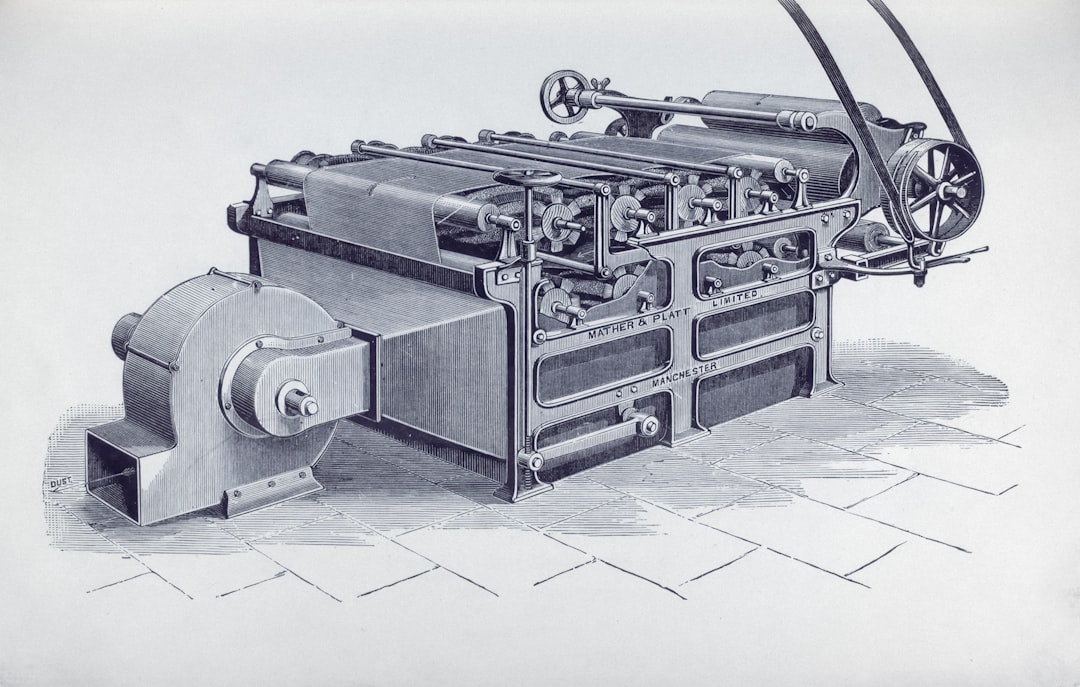

Another best practice involves utilizing technology effectively to capture real-time data related to construction progress. Incorporating tools such as laser scanning or BIM can significantly enhance the accuracy of as-built documentation by providing precise measurements and visual representations of completed work.

The Future of Comparing As-Built Drawings to Real Life: Innovations and Trends

The future of comparing as-built drawings to real-life conditions is poised for exciting innovations driven by advancements in technology. Emerging trends such as artificial intelligence (AI) and machine learning are beginning to play a role in automating the comparison process by analyzing vast amounts of data quickly and accurately. These technologies can identify discrepancies more efficiently than traditional methods, allowing teams to focus on resolving issues rather than spending time on manual comparisons.

Additionally, augmented reality (AR) is set to transform how professionals interact with as-built drawings on-site. By overlaying digital information onto physical environments through AR devices, teams can visualize discrepancies in real-time and make informed decisions about necessary adjustments immediately. As these technologies continue to evolve, they will undoubtedly enhance the accuracy and efficiency of comparing as-built drawings to real-life conditions in construction projects moving forward.

As-built drawings are crucial for accurately representing the final state of a construction project, but they often differ from the actual reality on-site. For a deeper understanding of this topic, you can explore the article on the importance of as-built documentation in construction projects, which can be found here. This resource provides valuable insights into how discrepancies between as-built drawings and the actual construction can impact project outcomes.

WATCH THIS! The Map You Can’t See: America’s $50 Billion Secret Underground City

FAQs

What are as-built drawings?

As-built drawings are revised versions of construction drawings submitted by contractors upon completion of a project. They reflect all changes made during construction, showing the exact dimensions, locations, and specifications as the building was actually constructed.

How do as-built drawings differ from original design drawings?

Original design drawings represent the architect’s or engineer’s initial plans and specifications before construction begins. As-built drawings document any modifications, deviations, or adjustments made during construction, providing an accurate record of the final built structure.

Why might there be differences between as-built drawings and the actual reality on site?

Differences can arise due to unforeseen site conditions, design changes during construction, errors or omissions, contractor substitutions, or adjustments made to meet regulatory or practical requirements. These factors can cause the built structure to deviate from both the original design and the as-built drawings if updates are not accurately recorded.

How important are as-built drawings for facility management?

As-built drawings are crucial for facility management because they provide an accurate reference for maintenance, renovations, repairs, and future expansions. They help ensure that any work done on the building is based on the actual conditions rather than outdated or incorrect plans.

Can as-built drawings be considered 100% accurate representations of the built structure?

While as-built drawings aim to be accurate, they may not always perfectly reflect reality due to human error, incomplete documentation, or changes made after the drawings were finalized. Verification through site surveys or digital scanning technologies is often necessary for critical applications.

What technologies are used to improve the accuracy of as-built drawings?

Technologies such as 3D laser scanning, photogrammetry, Building Information Modeling (BIM), and drones are increasingly used to capture precise measurements and create detailed as-built documentation, reducing discrepancies between drawings and reality.

Who is responsible for producing as-built drawings?

Typically, the contractor or construction team is responsible for updating and submitting as-built drawings. However, architects, engineers, or specialized surveyors may also be involved in verifying and producing accurate as-built documentation.

How can discrepancies between as-built drawings and reality be minimized?

Discrepancies can be minimized by maintaining thorough communication during construction, regularly updating drawings to reflect changes, using advanced measurement technologies, conducting frequent site inspections, and involving all stakeholders in the documentation process.