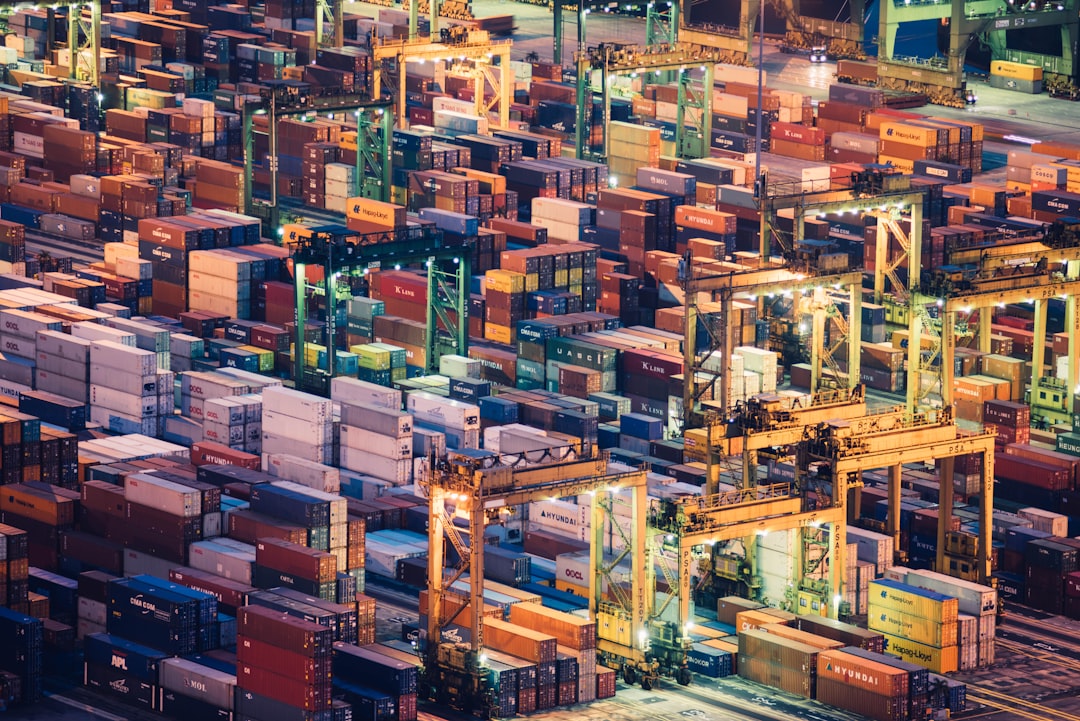

The supply chain crisis has emerged as a significant challenge for businesses and consumers alike, particularly in the wake of global disruptions such as the COVID-19 pandemic. This crisis is characterized by delays, shortages, and increased costs that have reverberated across various industries. As companies struggle to meet consumer demand, the complexities of the supply chain have become increasingly apparent.

The interconnectedness of global trade means that a disruption in one region can have cascading effects worldwide, leading to a ripple effect that impacts everything from manufacturing to retail. In recent years, the fragility of supply chains has been laid bare, prompting a reevaluation of how goods are produced and delivered. The crisis has highlighted the importance of understanding not just the logistics of supply chains but also the broader economic and social factors that influence them.

As businesses grapple with these challenges, it becomes essential to analyze the underlying issues that contribute to supply chain disruptions and to develop strategies for navigating this complex landscape.

Key Takeaways

- The supply chain crisis is impacting businesses and consumers globally, leading to disruptions in production and distribution.

- Root causes of the crisis include labor shortages, raw material shortages, transportation challenges, and increased demand for certain products.

- Businesses and consumers are experiencing delays, increased costs, and limited product availability as a result of the supply chain crisis.

- Strategies for managing supply chain disruptions include diversifying suppliers, optimizing inventory levels, and investing in technology and data analytics.

- Building resilience in the supply chain involves creating contingency plans, fostering strong supplier relationships, and implementing agile and flexible processes.

Identifying the Root Causes of the Crisis

Several factors have converged to create the current supply chain crisis, each contributing to the overall disruption in unique ways. One of the primary causes has been the pandemic itself, which led to widespread factory shutdowns, labor shortages, and transportation bottlenecks. As countries implemented lockdowns and restrictions, production slowed or halted entirely, creating a backlog of orders that would take months to resolve.

This sudden shift in supply dynamics caught many businesses off guard, revealing vulnerabilities in their operational frameworks. Additionally, geopolitical tensions and trade disputes have exacerbated the situation. Tariffs and sanctions can disrupt established trade routes and increase costs for businesses reliant on international suppliers.

Furthermore, natural disasters and climate change have introduced an element of unpredictability into supply chains, as extreme weather events can damage infrastructure and disrupt logistics. Understanding these root causes is crucial for businesses seeking to mitigate risks and develop more robust supply chain strategies moving forward.

Impact of the Crisis on Businesses and Consumers

The ramifications of the supply chain crisis are far-reaching, affecting both businesses and consumers in profound ways. For companies, the inability to secure necessary materials or products has led to production delays, increased operational costs, and ultimately, a decline in profitability. Many businesses have been forced to make difficult decisions, such as reducing their workforce or scaling back operations, in response to these challenges.

The crisis has also prompted a reevaluation of inventory management practices, as companies strive to balance supply with fluctuating consumer demand. Consumers have not been spared from the fallout either. The crisis has manifested in empty shelves at grocery stores, delayed shipments for online orders, and rising prices for everyday goods.

As consumers face longer wait times for products and increased costs, their purchasing behavior may shift, leading to changes in market dynamics. The frustration felt by consumers can also translate into brand loyalty issues for businesses that struggle to meet expectations during this tumultuous period.

Strategies for Managing Supply Chain Disruptions

| Strategy | Description |

|---|---|

| Inventory Optimization | Implementing inventory management techniques to reduce excess inventory and stockouts. |

| Supplier Diversification | Identifying and working with multiple suppliers to reduce dependency on a single source. |

| Risk Assessment and Mitigation | Conducting risk assessments and developing plans to mitigate potential disruptions. |

| Technology Integration | Utilizing technology such as AI, IoT, and blockchain to improve visibility and agility in the supply chain. |

| Collaborative Relationships | Building strong relationships with suppliers, customers, and partners to enhance communication and collaboration. |

To navigate the complexities of the supply chain crisis, businesses must adopt proactive strategies that allow them to manage disruptions effectively. One approach is diversifying suppliers to reduce reliance on a single source for critical materials or products. By establishing relationships with multiple suppliers across different regions, companies can mitigate risks associated with localized disruptions.

This strategy not only enhances flexibility but also fosters competition among suppliers, potentially leading to better pricing and service. Another effective strategy involves enhancing visibility throughout the supply chain. By leveraging data analytics and real-time tracking systems, businesses can gain insights into their supply chain operations and identify potential bottlenecks before they escalate into larger issues.

This level of transparency enables companies to make informed decisions quickly, ensuring that they can respond effectively to changing circumstances. Additionally, investing in employee training and development can empower teams to adapt to new challenges and implement innovative solutions.

Building Resilience in the Supply Chain

Building resilience within the supply chain is essential for long-term sustainability and success. Resilience refers to a system’s ability to anticipate, prepare for, respond to, and recover from disruptions effectively. Companies can enhance their resilience by adopting a holistic approach that encompasses risk assessment, contingency planning, and continuous improvement.

Conducting regular risk assessments allows businesses to identify vulnerabilities within their supply chains and develop strategies to address them proactively. Moreover, fostering a culture of collaboration among stakeholders is vital for building resilience. By engaging suppliers, logistics partners, and even customers in discussions about potential risks and solutions, companies can create a more robust support network.

This collaborative approach not only strengthens relationships but also encourages innovation as stakeholders work together to find creative solutions to shared challenges.

Leveraging Technology to Navigate the Crisis

Technology plays a pivotal role in helping businesses navigate the complexities of the supply chain crisis. Advanced technologies such as artificial intelligence (AI), machine learning, and blockchain can provide valuable insights into supply chain operations and enhance decision-making processes. For instance, AI-driven analytics can help companies forecast demand more accurately, allowing them to adjust production schedules accordingly and minimize excess inventory.

Blockchain technology offers another layer of transparency by enabling secure and traceable transactions throughout the supply chain. This technology can help businesses verify the authenticity of products, track their movement in real-time, and ensure compliance with regulations. By leveraging these technological advancements, companies can not only improve their operational efficiency but also build trust with consumers who increasingly demand transparency in sourcing and production practices.

Collaborating with Suppliers and Partners

Collaboration with suppliers and partners is essential for navigating the challenges posed by the supply chain crisis. Establishing strong relationships with key suppliers can lead to improved communication and responsiveness during times of disruption. By working closely with suppliers to understand their capabilities and constraints, businesses can develop more effective contingency plans that account for potential delays or shortages.

Furthermore, collaboration extends beyond suppliers; it includes logistics providers, distributors, and even competitors in some cases. Industry partnerships can foster knowledge sharing and innovation as companies come together to address common challenges. Collaborative initiatives such as joint purchasing agreements or shared logistics networks can help reduce costs and improve efficiency across the supply chain.

Communicating Effectively with Stakeholders

Effective communication is paramount during a supply chain crisis. Businesses must keep stakeholders informed about potential disruptions and their impact on operations. Transparent communication helps build trust with customers, employees, investors, and suppliers alike.

By providing regular updates on inventory levels, delivery timelines, and any changes in operations, companies can manage expectations and mitigate frustration among stakeholders. Moreover, fostering an open dialogue with employees is crucial for maintaining morale during challenging times. Engaging employees in discussions about supply chain challenges can empower them to contribute ideas for improvement and foster a sense of ownership over solutions.

Implementing Inventory Management Best Practices

Effective inventory management is a cornerstone of successful supply chain operations, particularly during times of crisis. Businesses must adopt best practices that allow them to balance supply with demand while minimizing excess inventory costs. One approach is implementing just-in-time (JIT) inventory systems that align production schedules closely with customer demand.

This strategy reduces holding costs but requires precise forecasting and strong supplier relationships. Additionally, utilizing inventory management software can enhance visibility into stock levels and streamline order fulfillment processes.

By optimizing inventory management practices, companies can improve their responsiveness to market fluctuations while minimizing waste.

Exploring Alternative Sourcing and Logistics Options

In light of the ongoing supply chain crisis, exploring alternative sourcing and logistics options has become increasingly important for businesses seeking stability. Companies may consider reshoring or nearshoring production facilities closer to their target markets to reduce reliance on distant suppliers and mitigate transportation delays. This shift not only shortens lead times but also allows businesses to respond more quickly to changing consumer preferences.

Additionally, diversifying logistics providers can enhance flexibility in transportation options. By establishing relationships with multiple carriers or utilizing third-party logistics (3PL) providers, companies can adapt more easily to disruptions in shipping routes or capacity constraints. Exploring alternative modes of transportation—such as rail or air freight—can also provide additional options for expediting shipments when necessary.

Planning for the Future: Lessons Learned and Long-Term Solutions

As businesses emerge from the current supply chain crisis, it is essential to reflect on lessons learned and develop long-term solutions that enhance resilience moving forward. One key takeaway is the importance of agility; companies must be prepared to pivot quickly in response to changing market conditions or unexpected disruptions. This agility requires ongoing investment in technology, training, and supplier relationships.

Furthermore, fostering a culture of continuous improvement will be vital for long-term success. Businesses should regularly assess their supply chain strategies and seek opportunities for optimization based on evolving best practices and emerging trends. By embracing innovation and collaboration as core principles of their operations, companies can position themselves for success in an increasingly complex global marketplace.

In conclusion, navigating the supply chain crisis requires a multifaceted approach that encompasses understanding root causes, implementing effective strategies, leveraging technology, fostering collaboration, communicating transparently with stakeholders, optimizing inventory management practices, exploring alternative sourcing options, and planning for future resilience. By taking these steps, businesses can not only weather current challenges but also emerge stronger in an ever-evolving landscape.

The ongoing supply chain crisis has been a significant challenge for businesses worldwide, affecting everything from manufacturing to retail. Companies are struggling to keep up with demand due to disruptions in logistics and transportation. For a deeper understanding of how these disruptions are impacting various industries, you can explore a related article on the topic by visiting this page. This article provides insights into the causes of the crisis and potential strategies for mitigation, offering valuable information for businesses looking to navigate these turbulent times.

WATCH NOW! Unlocking Disaster: 7 Choke Points That Could Fracture Our Connected World Overnight

FAQs

What is a supply chain crisis?

A supply chain crisis refers to a disruption in the flow of goods and services within a supply chain, leading to delays, shortages, and increased costs.

What are the causes of a supply chain crisis?

Causes of a supply chain crisis can include natural disasters, geopolitical events, economic downturns, transportation disruptions, and unexpected demand fluctuations.

How does a supply chain crisis impact businesses?

A supply chain crisis can impact businesses by causing production delays, inventory shortages, increased costs, and ultimately, loss of revenue and customer dissatisfaction.

What industries are most affected by supply chain crises?

Industries that rely heavily on global sourcing, just-in-time inventory management, and complex logistics are most affected by supply chain crises. This includes industries such as automotive, electronics, retail, and pharmaceuticals.

How can businesses mitigate the impact of a supply chain crisis?

Businesses can mitigate the impact of a supply chain crisis by diversifying suppliers, maintaining safety stock, improving supply chain visibility, and implementing risk management strategies.

What are some recent examples of supply chain crises?

Recent examples of supply chain crises include the COVID-19 pandemic, the Suez Canal blockage, and the global semiconductor shortage.