When considering construction projects, the choice of aggregate materials plays a pivotal role in the durability, strength, and overall success of any build. Among the most ubiquitous construction aggregates are sand – specifically, river sand and desert sand. These two seemingly similar materials, born from vastly different geological environments, possess distinct characteristics that make them suitable or unsuitable for various construction applications. Understanding these differences is crucial for engineers, builders, and specifiers to ensure the integrity and longevity of structures. This article will delve into a comprehensive comparison of river sand and desert sand for construction purposes, examining their origins, physical properties, chemical compositions, and subsequent implications for their use.

The genesis of sand is a story etched in time, spanning millennia of erosion, weathering, and transport. The environment in which sand is formed profoundly influences its characteristics, much like the childhood experiences that shape an individual.

River Sand: The Sculptural Power of Flowing Water

River sand is the product of relentless fluvial action. Over vast stretches of time, the flowing water in rivers acts as a persistent sculptor, breaking down larger rock formations at their source into smaller particles. This process doesn’t happen in a single day; it is the cumulative effect of countless water molecules, carrying abrasive sediment, grinding against rock faces.

Weathering Processes at the River Source

The initial breakdown of parent rock material begins with weathering. This can occur through various mechanisms:

- Physical Weathering: This involves the mechanical disintegration of rocks without a change in their chemical composition. Examples include:

- Freeze-Thaw Cycles: Water seeps into rock crevices, freezes, expands, and widens the cracks. Repeated cycles can shatter rock fragments.

- Thermal Expansion and Contraction: Daily and seasonal temperature fluctuations cause rock minerals to expand and contract at different rates, leading to stress and fracturing.

- Abrasion: Wind and water-borne particles act like sandpaper, grinding away at rock surfaces.

- Chemical Weathering: This involves the decomposition of rocks through chemical reactions. Examples include:

- Hydrolysis: Water reacts with minerals, breaking them down into new compounds.

- Oxidation: Minerals react with oxygen, forming oxides (similar to rust on iron).

- Carbonation: Carbon dioxide dissolved in rainwater forms carbonic acid, which reacts with and dissolves carbonate rocks like limestone.

Transportation and Rounding by Water Currents

Once broken down, these rock fragments are carried downstream by the river. The journey is a long and arduous one, and it is during this transportation that river sand acquires its characteristic shape.

- Constant Impact and Abrasion: As the sand particles are tossed and tumbled along the riverbed, they collide with each other and with the riverbed itself. This continuous grinding and impact effect wears down sharp edges and corners, progressively smoothing and rounding the particles.

- Sorting by Flow Dynamics: The speed and turbulence of the water current play a significant role in sorting the sand. Finer particles are carried further downstream and deposited in calmer areas, while coarser particles settle out earlier. This natural stratification leads to a more uniform particle size distribution within a given riverbed deposit.

- Washing and Purification: The constant flow of water also has a cleansing effect, washing away lighter impurities like silt and clay. While not always complete, this process generally results in cleaner sand compared to its desert counterpart.

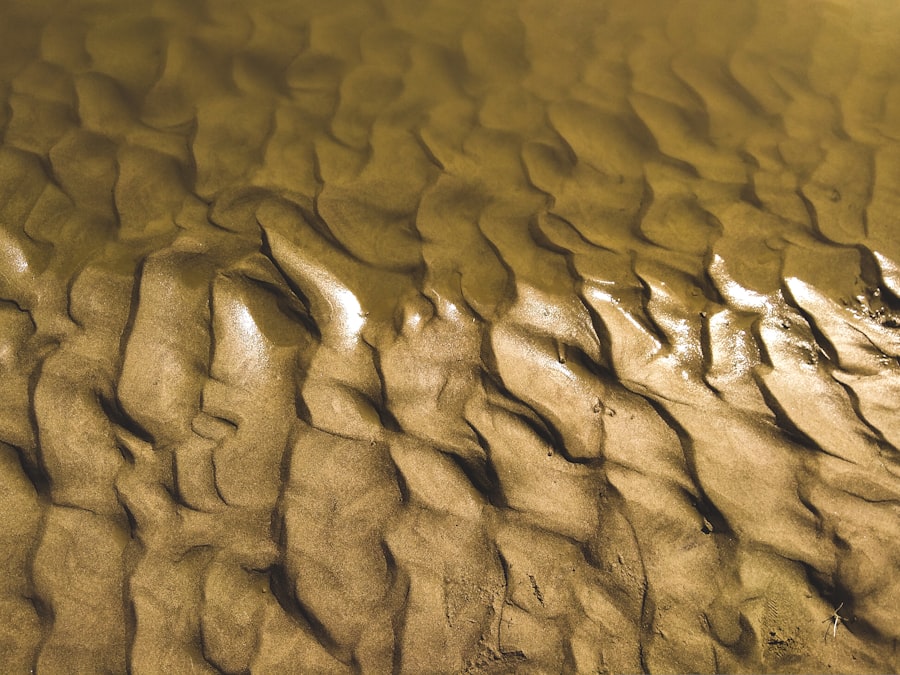

Desert Sand: The Legacy of Arid Landscapes

Desert sand, on the other hand, owes its existence primarily to the wind and the harsh, dry conditions of arid environments. The processes of formation and transport are fundamentally different, leading to a distinct set of properties.

Long-Term Erosion in Arid Climates

The relentless forces of weathering and erosion in deserts operate at a much slower pace than in river systems, but over vast geological timescales, they are equally effective.

- Wind Erosion (Aeolian Processes): Wind is the primary sculptor of desert landscapes and desert sand. It achieves this through several mechanisms:

- Deflation: Wind lifts and carries away loose particles from the surface, leaving behind coarser material. This can lower the ground level over time.

- Abrasion: Wind-borne sand particles act as a potent erosive agent, sandblasting rocks and other surfaces, gradually wearing them down. Imagine millions of tiny hammers striking a surface incessantly.

- Saltation: The bouncing and skipping motion of sand grains along the ground is a major contributor to wind erosion. These bouncing grains dislodge other particles, perpetuating the process.

- Limited Chemical Weathering: The scarcity of water in deserts significantly limits the rate of chemical weathering. While some salt weathering (crystallization of salts within rock pores causing expansion and disintegration) can occur, it is generally less impactful than in humid environments.

Transport and Angularity by Wind

The transport of sand by wind results in a very different particle shape and composition.

- Less Frequent and Less Intense Collisions: While desert sand particles do collide during transport, the collisions are typically less frequent and less forceful than those experienced by river sand. The air is a much less dense medium than water, offering less resistance and momentum, resulting in fewer, gentler impacts.

- Preservation of Sharp Edges: Consequently, desert sand particles tend to retain their original angularity. They do not undergo the extensive rounding that is characteristic of river sand. This angularity is a crucial distinguishing feature with significant implications for construction.

- Presence of Finer Deducible Material: Wind, while capable of moving sand, is less effective at fully removing very fine materials like silt and clay from the sand particles themselves. This can lead to a higher proportion of these finer impurities within desert sand deposits, often clinging to the larger grains.

When considering the materials used for construction, it’s essential to understand the differences between river sand and desert sand. River sand, with its rounded grains and higher cohesiveness, is often preferred for concrete and mortar, while desert sand, being finer and more angular, may not provide the same structural integrity. For a deeper insight into this topic, you can read the related article at this link.

Physical Properties: The Tangible Differences

The distinct origins of river and desert sand manifest in readily observable physical properties that directly influence their performance in construction. These properties are not mere academic curiosities; they are the bedrock of a material’s suitability for a specific task.

Particle Shape and Texture: Sharpness vs. Smoothness

The most striking visual difference between river and desert sand lies in the shape and texture of individual grains. This is a direct consequence of the transport mechanisms.

River Sand: Rounded and Smooth Grains

As established, the tumbling and grinding action of water during transport effectively rounds the sharp edges of rock fragments.

- Smoother Surfaces: The surfaces of river sand grains are generally smoother due to abrasion. This smoothness can affect the interlocking and bonding capabilities of the sand within concrete or mortar mixes.

- Lower Inter-particle Friction: Rounded particles exhibit lower friction when they slide past each other. This can be detrimental in applications where high internal friction is desired, such as in the stability of granular materials.

- Easier Compaction (but potentially weaker bond): While rounded particles might seem to lend themselves to easier compaction due to their ability to nestle together, the bond between them might be weaker due to the reduced surface area for interlocking.

Desert Sand: Angular and Sharp Grains

The limited abrasion during wind transport leaves desert sand particles with sharp edges and irregular surfaces.

- Rough Surfaces: The angular nature creates a rougher surface texture. This increased roughness can be advantageous in certain construction applications.

- Higher Inter-particle Friction: The sharp edges allow for greater interlocking between particles. This leads to higher internal friction, contributing to increased shear strength and stability in granular materials. Think of how a pile of sharp rocks will hold its shape better than a pile of marbles.

- Increased Surface Area (for bonding): The irregular shapes and sharp edges provide a larger effective surface area for bonding with cement paste in concrete or mortar. This can lead to stronger interfacial bonds and potentially higher compressive strength.

Particle Size Distribution (Gradation): The Mix of Grains

The range and proportion of different particle sizes within a sand sample, known as its gradation, are critical for its performance. This is influenced by both the origin and the method of extraction or collection.

River Sand: Generally Well-Graded (but can vary)

River sand deposits often exhibit a natural tendency towards being well-graded. This means they contain a good mix of fine, medium, and coarse particles.

- “Goldilocks” Mixture: A well-graded sand is often referred to as having the “just right” mixture of particle sizes. Smaller particles fill the voids between larger particles, leading to a denser and more compact material.

- Reduced Void Content: This efficient packing results in a lower void content, meaning less empty space within the material. This is highly desirable in concrete and mortar mixes, as it reduces the amount of cement paste required to fill these voids, leading to cost savings and improved strength.

- Enhanced Workability: A well-graded sand can improve the workability of concrete and mortar mixtures, making them easier to mix, place, and finish.

- Potential for Oversized or Undersized Fractions: However, river sand deposits can vary. Some sections might be dominated by finer particles (leading to excessive fines), while others might have a higher proportion of coarser grains. Screening and sieving are often necessary to achieve the desired gradation.

Desert Sand: Often Uniformly Graded (or poorly graded)

Desert sand is frequently characterized by a more uniform particle size distribution, meaning most of the grains are of a similar size.

- Poor Interlocking (if consistently sized): If the desert sand is uniformly graded with a narrow range of particle sizes, the particles will not fit together as efficiently as in a well-graded mix. This leads to higher void content.

- Increased Void Content: The larger voids require more cement paste to fill, increasing material costs and potentially reducing the overall strength if not carefully managed. It’s like trying to build a wall with only marbles – there will be a lot of empty space.

- Presence of a “Dust” Fraction: Desert sand is also often accompanied by a significant amount of very fine dust (silt and clay). This fine fraction, if not adequately removed, can negatively impact the performance of concrete and mortar. It can:

- Reduce Bond Strength: The dust acts as a weak interface between cement paste and sand particles.

- Increase Water Demand: Finer particles require more water to achieve a workable mix, which can lead to higher water-cement ratios and reduced strength.

- Cause Shrinkage and Cracking: Excess fines can contribute to increased drying shrinkage and subsequent cracking in hardened concrete.

- Potential for Coarse Aggregates: In some desert deposits, larger, more angular aggregate particles may also be present alongside the sand.

Bulk Density and Specific Gravity: Weight Matters

These properties relate to how much a volume of sand weighs and how dense the solid material itself is. They have implications for transportation costs and the final density of construction materials.

River Sand: Generally Higher Bulk Density

Due to its more rounded shape and better gradation, river sand tends to pack more tightly, resulting in a higher bulk density.

- Efficient Packing: The ability of rounded particles to nestle together leads to less air being trapped within a given volume.

- Lower Void Ratio: This directly translates to a lower void ratio.

- Cost-Effective Transportation: A higher bulk density means more material can be transported per unit volume, potentially reducing transportation costs.

- Contribution to Dense Concrete: Higher density of the aggregate can contribute to a denser and potentially stronger final concrete product.

Desert Sand: Generally Lower Bulk Density

The angularity and often poorer gradation of desert sand mean that particles do not pack as efficiently.

- Higher Void Ratio: More air pockets are trapped between the sharp, irregular grains.

- Lower Bulk Density: Consequently, a given volume of desert sand will weigh less than the same volume of river sand.

- Increased Transportation Costs: More trips or larger vehicles may be needed to transport the same mass of material.

- Potential for Lighter Structures: In some niche applications where weight is a concern, the lower bulk density might be a marginal advantage, though this is rarely the primary driver for sand selection.

Absorption and Moisture Content: The Thirst of Sand

The ability of sand to absorb water is critical, especially in concrete and mortar mixes, as it affects the water-cement ratio and the overall consistency of the mix.

River Sand: Lower Absorption Rates

River sand, having been extensively washed by water, typically has fewer porous particles and a lower tendency to absorb water.

- Less Water Assimilation: Individual grains of river sand are less likely to soak up water like a sponge.

- Predictable Water-Cement Ratio: This predictability is invaluable for concrete mix design. The amount of water added can be more accurately controlled, leading to consistent strength and durability.

- Reduced Impact on Workability: The lower absorption means that the mix’s workability is less likely to be significantly altered by the sand’s moisture content, provided it’s within reasonable limits.

Desert Sand: Higher Absorption Rates (can be variable)

Desert sand, particularly if it contains more porous rock fragments or has adhered fine particles, can exhibit higher absorption rates.

- “Dry” Desert Sand is Deceptive: Even seemingly dry desert sand can have a significant internal capacity for holding moisture.

- Complication of Mix Design: This variable absorption makes precise control of the water-cement ratio more challenging. Estimating the actual water demand of the mix requires careful consideration of the sand’s absorption characteristics.

- Potential for Inconsistent Workability: If the moisture content of desert sand varies, it can lead to unpredictable changes in the workability of the concrete or mortar.

Chemical Composition: Purity and Reactivity

Beyond their physical form, the chemical makeup of sand is equally important. Certain chemical constituents can have detrimental effects on the long-term performance of construction materials.

River Sand: Generally Low in Harmful Impurities

The continuous washing action in rivers tends to remove soluble salts and other reactive impurities.

- Reduced Soluble Salts: River sand generally contains lower levels of soluble salts, such as chlorides and sulfates. These salts can contribute to:

- Corrosion of Reinforcement: In reinforced concrete, chlorides can penetrate the concrete cover and attack the steel reinforcement, leading to rust and expansion, which can crack the concrete.

- Sulfate Attack: Sulfates can react with cementitious materials, leading to expansion and deterioration of the concrete.

- Minimal Organic Matter: Organic matter, such as decaying plant material, can interfere with the hydration of cement and reduce the strength of the hardened material. River transport often washes away such contaminants.

- Inert Constituents: The parent rock material that forms river sand is often composed of relatively inert minerals like quartz, feldspar, and certain igneous and metamorphic rocks, which are stable in construction environments.

Desert Sand: Potential for Higher Impurities

Desert environments can trap and retain various substances that are detrimental to construction.

- High Soluble Salt Content: The evaporation of scarce water in deserts concentrates soluble salts on and within sand particles. These can include:

- Chlorides: Particularly problematic in coastal or areas where salts are naturally prevalent.

- Sulfates: High sulfate content can lead to detrimental reactions with cement.

- Alkali Carbonates: These can cause efflorescence (white powdery deposits on the surface) and alkali-aggregate reactions, which can lead to cracking and deterioration of concrete.

- Presence of Clay and Silt: As mentioned, wind is less effective at removing fine particles like clay and silt from desert sand. These can:

- Adhere to Sand Grains: Reducing the surface area available for cement bonding.

- Impact Workability: Increase water demand and affect the flow properties of the mix.

- Reduce Strength: Act as a weak filler material.

- Potential for Reactive Minerals: Depending on the parent rock in the desert region, desert sand might contain a higher proportion of minerals that are susceptible to alkali-aggregate reactions, a damaging phenomenon that can cause concrete to expand and crack over time.

Construction Applications: Where Each Shines (or Stumbles)

The distinct properties of river and desert sand dictate their suitability for different roles in construction. This is not a matter of one being universally superior, but rather of matching the material to the specific demands of the application.

River Sand: The Workhorse of Concrete and Mortar

River sand is generally considered the preferred aggregate for most conventional concrete and mortar applications due to its favorable characteristics.

- Concrete Mixes: Its well-graded nature, rounded particles, and cleanliness contribute to:

- Good Workability: Making it easier to achieve a homogeneous mix that flows well into formwork.

- Optimal Packing: Reducing the amount of cement paste needed, leading to economical and strong concrete.

- High Compressive Strength: The efficient interlocking of particles and good bond with cement contribute to superior compressive strength.

- Durability: Low impurity content minimizes risks of chemical attack and long-term deterioration.

- Mortar for Masonry: In bricklaying and blockwork, river sand provides the necessary bulk and binding properties for the mortar.

- Adhesion: Its texture allows for good adhesion to mortar and masonry units.

- Workability: Facilitates easy application and bedding of bricks or blocks.

- Plastering and Rendering: For building facades and internal walls, river sand offers a smooth finish and good binding properties.

- Aesthetic Finish: Its typically finer texture allows for a smoother plaster.

- Durability: Contributes to a robust and crack-resistant finish.

- Other Applications: River sand also finds use in asphalt mixes, drainage layers, and as a general fill material.

Desert Sand: Niche Uses and Special Considerations

Desert sand, while often less ideal for general-purpose concrete and mortar, can be utilized in specific circumstances, often with significant pre-treatment or in less structurally demanding applications.

- Asphalt Concrete: Due to its angularity, desert sand can sometimes be advantageous in asphalt mixes.

- Increased Stability: The interlocking of angular particles can enhance the stability and rutting resistance of asphalt pavements, particularly under heavy traffic loads.

- Adhesion: The rough surface can improve the adhesion between the asphalt binder and the aggregate.

- Limited Use in Concrete (with caveats): When desert sand is used in concrete, stringent measures are essential to mitigate its drawbacks:

- Thorough Washing and Screening: Essential to remove clay, silt, and soluble salts. This is a critical step to make it usable.

- Careful Gradation Control: Blending with other aggregates or artificial grading might be necessary to achieve a well-graded mix.

- Control of Water-Cement Ratio: Precise management of water is crucial to account for potential variations in absorption.

- Potential for Strength Reduction: Even with treatment, the inherent properties of desert sand may limit the ultimate strength and durability compared to river sand.

- Fill Material: In applications where structural integrity is not paramount, its inherent lower cost in some desert regions might make it suitable as general fill material.

- Landscaping and Decorative Uses: Outside of structural applications, desert sand is commonly used for decorative purposes, creating specific aesthetics.

When considering materials for construction, the differences between river sand and desert sand can significantly impact the quality and durability of the final product. River sand, known for its smooth texture and angular grains, is often preferred for concrete and mortar, while desert sand tends to be finer and more rounded, making it less suitable for such applications. For a deeper understanding of these distinctions and their implications in construction practices, you can read more in this informative article on myGeoQuest.

Quality Control and Treatment: Bridging the Gap

| Property | River Sand | Desert Sand | Impact on Construction |

|---|---|---|---|

| Grain Shape | Rounded to sub-rounded | Very smooth and well-rounded | River sand’s angularity improves bonding with cement; desert sand’s smoothness reduces bonding strength. |

| Grain Size | Varied sizes, generally coarser | Fine and uniform | Coarser grains provide better strength; fine grains may lead to weaker concrete. |

| Silica Content | High (around 70-90%) | High (around 85-95%) | High silica content is good for strength in both sands. |

| Impurities | May contain organic matter and silt | Generally low impurities | Impurities in river sand may require washing; desert sand is cleaner but less suitable due to shape. |

| Availability | Limited and regulated in many areas | Abundant in desert regions | Scarcity of river sand increases cost; desert sand is abundant but less used. |

| Water Absorption | Moderate | Low | Moderate absorption helps in cement hydration; low absorption may affect curing. |

| Suitability for Concrete | Highly suitable | Generally unsuitable without treatment | River sand preferred for structural concrete; desert sand may require processing or additives. |

The disparities between river and desert sand necessitate robust quality control measures and, in some cases, treatment processes to ensure their suitability for construction. The goal is to transform a potentially problematic material into one that meets the stringent demands of modern building practices.

River Sand: Routine Testing for Compliance

While generally preferred, river sand is not immune to potential issues. Quality control ensures it meets the required standards.

- Sieve Analysis: Performed to determine the particle size distribution and ensure it falls within specified ranges for different applications (e.g., ASTM C33 for fine aggregate in concrete). This checks for:

- Gradation: Verifying the presence of a suitable mix of particle sizes.

- Fineness Modulus: A measure of the average size of the sand particles, influencing workability.

- Organic Impurity Tests: To detect and quantify the presence of organic matter, which can impair cement hydration.

- Material Fineness Tests: Verifying the absence of excessive amounts of silt and clay.

- Soundness Tests: Assessing the resistance of the sand particles to disintegration when subjected to weathering processes.

- Chemical Tests: Particularly important in areas where contamination by soluble salts or other deleterious substances is a concern.

Desert Sand: Rigorous Pre-treatment and Testing

Desert sand almost always requires significant intervention to become a viable construction material. The focus here is on remediation.

- Washing: This is the most critical step. Large-scale washing plants are used to:

- Remove Clay and Silt: The water flushes away the fine, detrimental particles that cling to the sand grains.

- Reduce Soluble Salts: Washing can leach out a significant portion of soluble salts.

- Screening and Sieving: After washing, the sand is screened to remove any oversized particles and to achieve a desired gradation.

- Blending: Desert sand might be blended with other aggregates, such as washed river sand or crushed stone, to improve its gradation and overall performance.

- Salt Content Testing: Especially crucial after washing to ensure residual salt levels are within acceptable limits.

- Alkali-Aggregate Reaction Testing: If the source of desert sand is suspected to contain reactive minerals, specific tests (e.g., ASTM C1260) might be conducted.

- Absorption Tests: To accurately determine the water absorption capacity of the treated sand for mix design calculations.

- Chemical Treatments: In some extreme cases, chemical treatments might be employed to neutralize or remove specific harmful compounds, although this is less common due to cost and complexity.

In essence, the journey of desert sand from an arid landscape to a construction site often involves a transformative purification process, much like refining raw ore into a usable metal. This process adds cost and complexity, making treated desert sand less economically viable for many standard applications compared to naturally suitable river sand.

Cost-Effectiveness: The Economic Equation

The ultimate decision between using river sand and desert sand often hinges on economic considerations, balanced against performance requirements.

River Sand: Generally Higher Material Cost Where Scarce, But Lower Overall Cost for Quality

In regions with abundant river systems, river sand is often readily available and relatively inexpensive. However, in arid regions or areas with limited river access, river sand can become a premium material.

- Extraction and Processing Costs: While extraction from riverbeds is often simpler, transportation from distant sources can significantly increase costs.

- Natural Quality Advantage: The inherent desirable properties of river sand mean that less (or no) costly pre-treatment is required, making it more economically viable for high-performance applications.

- Reduced Material Quantity: As river sand is often well-graded, it requires less cement paste to achieve desired strength, leading to material cost savings in the final mix.

Desert Sand: Lower Initial Extraction Cost, Higher Processing Cost

In deserts, the raw material is often abundant and can be extracted with relative ease. However, the cost escalates significantly during the necessary treatment stages.

- Extraction Costs: Lower, as the material is often readily accessible.

- Washing and Treatment Costs: These are substantial. The capital investment in washing plants, the ongoing operational costs (water, energy, labor), and the transportation of treated sand all contribute to a higher overall cost, especially when aiming for high-quality construction.

- Potential for Increased Cement Content: If treatment is insufficient or if the sand is used in less demanding applications with lower quality control, a higher cement content might be required to compensate for poorer gradation and inherent impurities, further increasing project costs.

- Transportation Costs: Even after treatment, the lower bulk density of desert sand can translate to higher transportation costs per unit weight.

Therefore, while desert sand might appear cheaper at the point of extraction, the necessity of extensive processing and the potential need for higher cement content often make river sand a more cost-effective choice for critical construction elements, especially when factoring in long-term durability and maintenance. The economic argument is not solely about the initial purchase price, but about the total cost of ownership over the structure’s lifespan.

Conclusion: The Right Sand, For The Right Job

The comparison between river sand and desert sand for construction reveals that while both are forms of granular aggregate, their distinct origins endow them with vastly different properties. River sand, sculpted by the persistent flow of water, generally offers superior characteristics for its roundness, cleanliness, and consistent gradation. It is the reliable, well-behaved constituent that forms the backbone of countless robust structures. Desert sand, shaped by the arid winds, typically presents angularity, potential for higher impurities, and variable gradation.

For the vast majority of conventional construction applications, particularly those requiring high strength and durability, river sand remains the preferred choice. Its natural suitability minimizes the need for extensive treatment and ensures predictable performance. Desert sand, conversely, plays a more specialized role. Its angularity can be beneficial in asphalt mixes, and once rigorously washed and treated to remove deleterious materials, it can be employed in concrete and mortar, albeit often with greater caution and a higher cost premium due to the necessary remediation.

Ultimately, the selection of sand for any construction project is an exercise in responsible material science. It requires a thorough understanding of the aggregate’s origin, its physical and chemical properties, and the specific demands of the intended application. By making informed decisions, engineers and builders can ensure that the sand they choose contributes to structures that stand the test of time, embodying both strength and longevity. The right sand, for the right job, is not merely a matter of convenience but a fundamental prerequisite for successful and sustainable construction.

WATCH NOW ▶️ WARNING: Why the World is Running Out of Sand (And You Never Noticed)

FAQs

What is the primary difference between river sand and desert sand?

River sand is naturally rounded and smooth due to water erosion, while desert sand is typically finer, more angular, and has a rough texture because it is shaped by wind erosion.

Why is river sand preferred over desert sand for construction?

River sand is preferred because its smooth and rounded particles provide better workability and bonding in concrete and mortar, whereas desert sand’s fine and angular particles do not bind well, leading to weaker construction materials.

Can desert sand be used in construction projects?

Desert sand is generally unsuitable for conventional construction due to its particle shape and size, but with proper treatment or blending with other materials, it can sometimes be used in specialized applications.

How does the grain size of river sand compare to that of desert sand?

River sand grains are usually coarser and more uniform in size, while desert sand grains are finer and more variable, which affects their suitability for construction purposes.

What impact does the source of sand have on the strength of concrete?

The source affects particle shape and size distribution; river sand’s rounded grains improve concrete strength and durability, whereas desert sand’s fine, angular grains can reduce strength and cause poor bonding in concrete mixes.