The cathode plant converter is a critical piece of equipment in copper production, used to extract and refine copper from ore. It operates through electrochemical processes that convert raw materials into high-purity copper cathodes. These cathodes are used in electrical wiring, plumbing, construction, and electronic devices.

Modern cathode plant converters represent the integration of advanced technology and engineering practices with environmental responsibility in metallurgical operations. Copper demand is increasing due to its applications in renewable energy systems and electric vehicles. As a result, the efficiency and performance of cathode plant converters have become increasingly important to the industry.

These converters have evolved significantly, incorporating technological improvements designed to increase production capacity while reducing environmental impact. Knowledge of cathode plant converter operations is essential for industry professionals, including engineers, plant operators, environmental compliance officers, and investors.

Key Takeaways

- Cathode plant converters are essential in copper production, facilitating the conversion process efficiently.

- Strict safety, environmental, and operational standards govern the design, maintenance, and use of these converters.

- Energy efficiency and automation play a critical role in optimizing converter performance and reducing power consumption.

- Regular maintenance, inspection, and quality control ensure reliable operation and high-quality copper output.

- Ongoing innovations and operator training are vital for advancing converter technology and meeting industry demands.

Understanding the Role of Cathode Plant Converter in the Production of Copper

The cathode plant converter is integral to the hydrometallurgical process of copper production, particularly in the electrowinning phase. In this process, copper ions are extracted from a leach solution containing dissolved copper, which is typically derived from oxidized ores or waste materials. The converter facilitates the electrolysis process, where an electric current is passed through the solution, causing copper ions to migrate towards the cathode, where they are deposited as solid copper.

This process not only enhances the purity of the copper produced but also allows for the recovery of valuable metals that may be present in the leach solution. The efficiency of the cathode plant converter directly influences the overall yield and quality of copper produced, making it a focal point for continuous improvement and innovation within the industry. By optimizing parameters such as current density and electrolyte composition, operators can significantly enhance production rates and reduce operational costs. Learn about the environmental impacts of lithium mining in this informative video.

Safety and Environmental Regulations for Cathode Plant Converter

Safety and environmental regulations are paramount in the operation of cathode plant converters. Given the potential hazards associated with handling chemicals and high-voltage equipment, strict adherence to safety protocols is essential to protect workers and surrounding communities. Regulatory bodies impose guidelines that dictate safe operating procedures, emergency response plans, and regular safety audits to ensure compliance with industry standards.

Moreover, environmental regulations play a critical role in mitigating the ecological impact of copper production. The cathode plant converter must operate within limits that minimize emissions and waste generation. This includes managing effluents from the electrolysis process and ensuring that any byproducts are treated or disposed of responsibly.

By implementing best practices in waste management and emissions control, operators can contribute to sustainable production methods while maintaining compliance with local and international environmental laws.

Material and Design Specifications for Cathode Plant Converter

The design and material specifications of cathode plant converters are crucial for their performance and longevity. Typically constructed from corrosion-resistant materials such as stainless steel or specialized alloys, these converters must withstand harsh chemical environments while maintaining structural integrity. The choice of materials not only affects durability but also influences the efficiency of the electrochemical processes taking place within the converter.

In addition to material selection, design considerations such as cell geometry, electrode configuration, and electrolyte flow dynamics play a significant role in optimizing performance. Engineers must carefully balance factors such as surface area for ion exchange and fluid dynamics to ensure uniform current distribution throughout the system. Innovations in design can lead to enhanced energy efficiency and improved recovery rates, making ongoing research and development in this area vital for advancing cathode plant technology.

Operating Temperature and Pressure Requirements for Cathode Plant Converter

| Parameter | Requirement | Unit | Notes |

|---|---|---|---|

| Output Current | 2000 – 4000 | Amperes (A) | Depends on cathode size and production rate |

| Output Voltage | 4 – 6 | Volts (V) | Low voltage for electrolysis process |

| Power Rating | 8 – 24 | kW | Based on current and voltage requirements |

| Efficiency | ≥ 95 | Percent (%) | High efficiency to reduce energy losses |

| Ripple Current | ≤ 5 | Percent (%) | Low ripple to ensure stable electrolysis |

| Cooling Method | Water-cooled or Air-cooled | N/A | Depends on converter design and environment |

| Control Type | Closed-loop feedback | N/A | For precise current regulation |

| Input Voltage | 380 – 480 | Volts AC (VAC) | Standard industrial supply voltage |

| Operating Temperature | -10 to 50 | °C | Ambient temperature range |

Operating temperature and pressure are critical parameters that influence the efficiency of cathode plant converters. Typically, these systems operate at elevated temperatures to enhance reaction kinetics and improve ion mobility within the electrolyte solution. However, maintaining optimal temperature levels is essential; excessive heat can lead to increased energy consumption and potential damage to equipment.

Pressure conditions also play a significant role in the electrolysis process. While most cathode plant converters operate at atmospheric pressure, certain advanced systems may utilize pressurized environments to further enhance ion transport and reaction rates. Operators must monitor these parameters closely to ensure that they remain within specified limits, as deviations can lead to reduced efficiency or even catastrophic failures.

Maintenance and Inspection Protocols for Cathode Plant Converter

Regular maintenance and inspection protocols are vital for ensuring the reliable operation of cathode plant converters. A comprehensive maintenance schedule typically includes routine checks on electrical systems, mechanical components, and chemical handling equipment. By identifying potential issues before they escalate into major problems, operators can minimize downtime and maintain consistent production levels.

Inspection protocols often involve visual assessments, performance testing, and analysis of wear patterns on critical components such as electrodes and cell linings. Advanced monitoring technologies, including sensors and data analytics tools, can provide real-time insights into system performance, allowing for proactive maintenance interventions. By fostering a culture of safety and diligence in maintenance practices, operators can extend the lifespan of their equipment while ensuring optimal operational efficiency.

Energy Efficiency and Power Consumption Considerations for Cathode Plant Converter

Energy efficiency is a paramount concern in the operation of cathode plant converters due to the significant power requirements associated with electrolysis processes. As energy costs continue to rise, operators are increasingly focused on optimizing power consumption without compromising production output. Strategies for enhancing energy efficiency may include optimizing current density settings, improving electrolyte circulation systems, and implementing advanced control algorithms.

Moreover, integrating renewable energy sources into the power supply for cathode plant converters presents an opportunity for further reducing carbon footprints. By utilizing solar or wind energy to supplement traditional power sources, operators can decrease reliance on fossil fuels while promoting sustainability within their operations. The pursuit of energy-efficient practices not only benefits operational costs but also aligns with global efforts toward reducing greenhouse gas emissions.

Quality Control and Testing Procedures for Cathode Plant Converter

Quality control is an essential aspect of cathode plant converter operations, ensuring that the copper produced meets industry standards for purity and performance. Rigorous testing procedures are implemented throughout the production process to monitor key parameters such as copper concentration, impurity levels, and physical properties of the cathodes produced. These tests help identify any deviations from expected outcomes, allowing for timely adjustments to be made.

In addition to routine quality assessments, advanced analytical techniques such as spectroscopy or chromatography may be employed to provide detailed insights into the composition of both raw materials and final products. By maintaining stringent quality control measures, operators can enhance customer satisfaction while minimizing waste associated with off-spec products.

Automation and Control Systems for Cathode Plant Converter

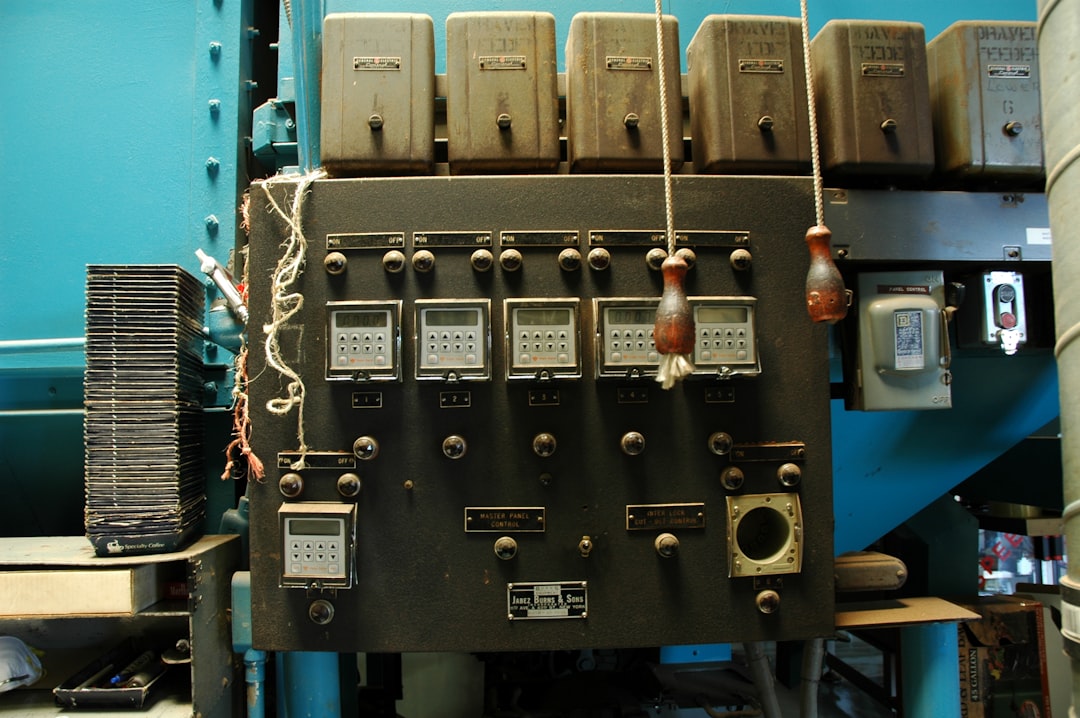

The integration of automation and control systems has revolutionized the operation of cathode plant converters. Modern systems utilize advanced software solutions that enable real-time monitoring and control of various operational parameters. This level of automation not only enhances efficiency but also reduces human error by providing precise control over critical processes such as current regulation and electrolyte management.

Furthermore, data analytics tools can be employed to analyze historical performance data, allowing operators to identify trends and optimize processes over time. Predictive maintenance algorithms can also be integrated into these systems to forecast potential equipment failures before they occur. By leveraging automation technologies, operators can achieve higher levels of productivity while ensuring consistent quality in their copper production processes.

Training and Certification Requirements for Operators of Cathode Plant Converter

The complexity of operating a cathode plant converter necessitates comprehensive training programs for personnel involved in its operation. Operators must possess a thorough understanding of electrochemical processes, safety protocols, and equipment maintenance procedures to ensure safe and efficient operations. Certification programs may be established by industry organizations or regulatory bodies to validate operators’ competencies in these areas.

Ongoing training is equally important as technology evolves and new methodologies are introduced into the industry. Continuous education programs can help operators stay abreast of advancements in cathode plant technology while reinforcing best practices in safety and efficiency. By investing in operator training and certification, companies can foster a skilled workforce capable of navigating the challenges associated with modern copper production.

Future Developments and Innovations in Cathode Plant Converter Technology

The future of cathode plant converter technology is poised for significant advancements driven by ongoing research and innovation within the field. Emerging trends include the development of more efficient electrolytes that enhance ion transport while reducing energy consumption during electrolysis processes. Additionally, advancements in materials science may lead to longer-lasting electrodes that improve overall system performance.

Moreover, as sustainability becomes an increasingly pressing concern within the industry, innovations aimed at reducing environmental impact will likely take center stage.

As stakeholders continue to prioritize sustainability alongside productivity, the evolution of cathode plant converters will reflect a commitment to responsible resource management while meeting global demands for copper in an ever-changing technological landscape.

This resource provides valuable insights into the technical specifications and regulatory standards necessary for efficient operation. You can read more about it in the following link: Cathode Plant Converter Requirements.

WATCH THIS! 🌍 “THE WATER IS GONE: Inside the Desert Killing the EV Revolution

FAQs

What is a cathode plant converter?

A cathode plant converter is an electrical device used in cathode production facilities to convert electrical power into the specific form required for the electrolysis process in metal refining, typically aluminum or copper.

Why are converter requirements important in a cathode plant?

Converter requirements are crucial to ensure the efficient, safe, and reliable operation of the electrolysis process. Proper specifications help maintain optimal current, voltage, and power quality, which directly affect the quality and yield of the cathode product.

What are the typical electrical specifications for cathode plant converters?

Typical specifications include the rated current (often several kiloamperes), voltage range (usually low voltage DC output), power capacity, efficiency, and the ability to handle transient loads and maintain stable output under varying operating conditions.

What types of converters are commonly used in cathode plants?

Common types include thyristor-based rectifiers, silicon-controlled rectifiers (SCR), and modern IGBT (Insulated Gate Bipolar Transistor) converters, which offer improved control, efficiency, and reduced harmonic distortion.

How do converter requirements affect energy consumption in cathode plants?

Converters with high efficiency and proper power factor correction reduce energy losses, lowering overall energy consumption and operational costs. Meeting converter requirements ensures minimal wasted energy during the electrolysis process.

What safety standards apply to cathode plant converters?

Converters must comply with electrical safety standards such as IEC, IEEE, and local regulations. These standards cover insulation, grounding, protection against overloads, short circuits, and electromagnetic compatibility to ensure safe operation.

How is converter performance monitored in a cathode plant?

Performance is monitored through parameters like output current and voltage, temperature, harmonic distortion, and efficiency. Advanced converters may include digital control systems for real-time monitoring and fault diagnostics.

Can cathode plant converters be customized?

Yes, converters can be customized to meet specific plant requirements, including size, power rating, control features, and integration with existing plant systems to optimize performance and compatibility.

What maintenance is required for cathode plant converters?

Regular maintenance includes inspection of cooling systems, electrical connections, control electronics, and replacement of worn components to ensure reliable operation and prevent downtime.

How do environmental conditions affect converter requirements?

Environmental factors such as temperature, humidity, dust, and corrosive atmospheres influence converter design and protection measures. Converters may require enclosures, cooling systems, and protective coatings to operate effectively in harsh conditions.