Permanent magnets are essential components across multiple industries, including electronics, automotive, renewable energy, and medical devices. These materials generate a continuous magnetic field without requiring external electrical power, making them valuable for applications ranging from electric motors to magnetic resonance imaging systems. The production of permanent magnets requires precise control of material composition, microstructure, and processing parameters to achieve desired magnetic properties.

The permanent magnet manufacturing industry has experienced significant growth due to increasing demand for energy-efficient technologies and miniaturized electronic devices. Modern applications require magnets with enhanced magnetic strength, improved temperature stability, and reduced weight compared to traditional materials. Manufacturing processes must balance performance requirements with cost considerations and material availability, particularly for rare earth elements used in high-performance magnets.

Current manufacturing approaches encompass both established powder metallurgy techniques and emerging additive manufacturing methods. Traditional processes include powder compaction, sintering, and machining, while newer technologies explore rapid solidification, hot deformation, and 3D printing applications. Environmental considerations have become increasingly important, driving development of recycling methods for rare earth materials and alternative magnet compositions that reduce dependence on critical raw materials.

Key Takeaways

- Traditional manufacturing techniques for permanent magnets face challenges like material limitations and production inefficiencies.

- Advanced methods, including additive manufacturing and powder metallurgy, offer improved precision and material properties.

- High-pressure processing and rapid solidification enhance magnetic performance and structural integrity.

- Surface treatment and coating are crucial for protecting magnets and extending their lifespan.

- Future trends focus on innovative manufacturing technologies and enhanced quality control to meet growing industry demands.

Traditional Manufacturing Techniques for Permanent Magnets

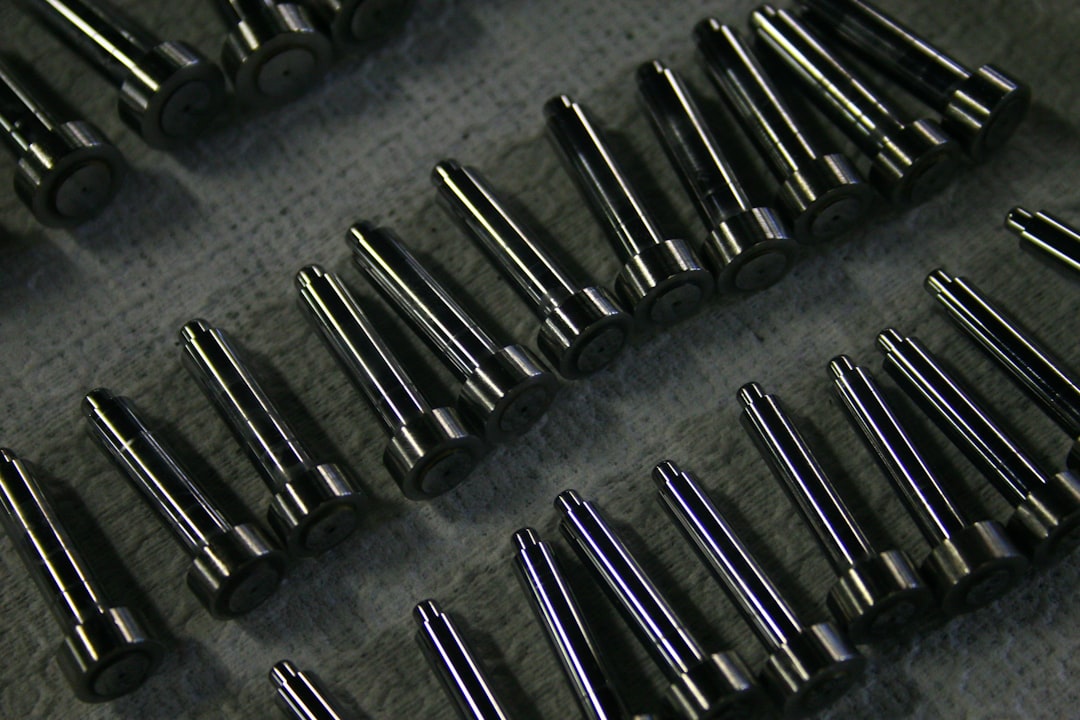

Traditional manufacturing techniques for permanent magnets primarily include sintering, casting, and machining. Sintering is one of the most widely used methods, where powdered materials are compacted and heated to form a solid mass without reaching the melting point. This process allows for the creation of dense and durable magnets, particularly in the case of ferrite and rare-earth magnets.

The sintering process can be tailored to achieve specific magnetic properties by adjusting parameters such as temperature, pressure, and time. Casting is another conventional method that involves pouring molten metal into a mold to create a magnet shape. This technique is often used for producing larger magnets or those with complex geometries.

While casting can yield high-quality magnets, it is limited by the types of materials that can be used and the cooling rates required to achieve optimal magnetic properties. Machining, on the other hand, involves shaping solid blocks of magnet material into desired forms using cutting tools. Although machining allows for precise dimensions and surface finishes, it can be wasteful in terms of material usage and may not be suitable for all types of magnet materials. China’s dominance in the global market is evident through its

Despite their widespread use, traditional manufacturing techniques for permanent magnets face several challenges and limitations. One significant issue is the reliance on rare-earth materials, which are often sourced from limited geographical locations. This dependence raises concerns about supply chain stability and environmental impact, as mining these materials can be ecologically damaging.

Additionally, fluctuations in market prices for rare-earth elements can lead to increased production costs, making it imperative for manufacturers to explore alternative materials or methods. Another challenge associated with traditional techniques is the inherent limitations in achieving uniform magnetic properties across large batches of magnets. Variability in material composition, processing conditions, and equipment can result in inconsistencies that affect performance.

Furthermore, traditional methods often require extensive post-processing steps to achieve desired magnetic characteristics, which can add time and cost to the manufacturing process. As industries demand higher performance and reliability from permanent magnets, addressing these challenges becomes increasingly critical.

Advanced Manufacturing Techniques for Permanent Magnets

In response to the limitations of traditional manufacturing methods, advanced techniques have emerged that offer improved efficiency and performance in permanent magnet production. One such technique is hot pressing, which combines heat and pressure to densify magnet powders into a solid form. This method not only enhances magnetic properties but also reduces processing time compared to conventional sintering.

Hot pressing allows manufacturers to create complex shapes with minimal waste while achieving superior magnetic performance. Another advanced technique gaining traction is spark plasma sintering (SPS). SPS utilizes pulsed electric currents to rapidly heat and densify materials at lower temperatures than traditional sintering methods.

This process minimizes grain growth and preserves fine microstructures, resulting in magnets with enhanced magnetic properties. The ability to control temperature and pressure precisely during SPS enables manufacturers to tailor the magnetic characteristics of their products more effectively than ever before.

Additive Manufacturing for Permanent Magnets

| Metric | Value | Unit | Description |

|---|---|---|---|

| Production Capacity | 5000 | tons/year | Annual production volume of permanent magnets |

| Material Composition | NdFeB 70%, SmCo 20%, Others 10% | Percentage | Typical material distribution in permanent magnet manufacturing |

| Coercivity (Hc) | 9000 | Oersted (Oe) | Resistance to demagnetization |

| Remanence (Br) | 1.2 | Tesla (T) | Residual magnetic flux density |

| Energy Product (BHmax) | 45 | MGOe | Maximum energy product indicating magnet strength |

| Manufacturing Yield | 95 | Percentage | Percentage of magnets meeting quality standards |

| Average Production Time | 3 | Days | Time taken to manufacture a batch of magnets |

| Operating Temperature Range | -40 to 150 | °C | Temperature range magnets can operate effectively |

Additive manufacturing (AM), commonly known as 3D printing, has emerged as a revolutionary approach in various fields, including permanent magnet production. This technique allows for the layer-by-layer construction of complex geometries that would be challenging or impossible to achieve with traditional methods. By utilizing AM, manufacturers can create customized magnet shapes tailored to specific applications while minimizing material waste.

One of the significant advantages of additive manufacturing in permanent magnet production is its potential for rapid prototyping.

Additionally, AM enables the integration of multiple materials within a single component, allowing for the development of hybrid magnets that combine different magnetic properties for enhanced performance.

Powder Metallurgy Techniques for Permanent Magnets

Powder metallurgy (PM) techniques have long been a cornerstone in the production of permanent magnets, particularly those made from iron-based alloys or rare-earth materials. PM involves the processing of metal powders into solid components through compaction and sintering. This method offers several advantages, including precise control over material composition and microstructure, which are critical for achieving desired magnetic properties.

In recent years, advancements in powder metallurgy have led to the development of new alloy compositions that enhance magnetic performance while reducing reliance on rare-earth elements. For instance, researchers have explored alternative materials such as iron-nitride compounds that exhibit promising magnetic characteristics without the environmental concerns associated with rare-earth mining. By leveraging innovative powder metallurgy techniques, manufacturers can produce high-performance permanent magnets that meet industry demands while promoting sustainability.

High-Pressure Processing Techniques for Permanent Magnets

High-pressure processing techniques have gained attention in the field of permanent magnet manufacturing due to their ability to enhance material properties significantly. One such technique is high-pressure torsion (HPT), which involves subjecting materials to extreme pressure while simultaneously applying torsional strain. This process refines microstructures at the atomic level, resulting in improved magnetic properties and mechanical strength.

HPT has shown promise in producing nanostructured magnets with superior performance characteristics compared to conventional methods. By manipulating microstructural features through high-pressure processing, manufacturers can achieve finer grain sizes and enhanced magnetic alignment within the material. This approach not only improves magnetic performance but also opens avenues for developing new magnet compositions that were previously deemed impractical.

Rapid Solidification Techniques for Permanent Magnets

Rapid solidification techniques have emerged as a game-changer in the production of permanent magnets by enabling the creation of unique microstructures that enhance magnetic properties. These techniques involve cooling molten materials at extremely high rates, resulting in amorphous or nanocrystalline structures that exhibit superior magnetic performance compared to their crystalline counterparts. One notable method within rapid solidification is melt spinning, where a molten alloy is ejected onto a rotating drum, forming thin ribbons that cool rapidly upon contact.

The resulting ribbons can be further processed into magnet powders or directly used as magnet components. The ability to control cooling rates during rapid solidification allows manufacturers to tailor magnetic properties precisely while minimizing defects commonly associated with traditional casting methods.

Surface Treatment and Coating Techniques for Permanent Magnets

Surface treatment and coating techniques play a vital role in enhancing the performance and longevity of permanent magnets. These processes aim to improve corrosion resistance, mechanical strength, and overall durability while maintaining optimal magnetic properties. Common surface treatments include electroplating, chemical coating, and physical vapor deposition (PVD).

Electroplating involves depositing a thin layer of metal onto the magnet’s surface to protect it from environmental factors such as moisture and oxidation. Chemical coatings can provide additional protection while also enhancing aesthetic appeal. PVD techniques allow for precise control over coating thickness and composition, enabling manufacturers to create tailored surface finishes that meet specific application requirements.

Quality Control and Testing Techniques for Permanent Magnets

Ensuring consistent quality in permanent magnet manufacturing is paramount for meeting industry standards and customer expectations. Quality control measures encompass various testing techniques designed to evaluate magnetic properties, dimensional accuracy, and overall performance. Common testing methods include flux density measurement, coercivity testing, and thermal stability assessments.

Flux density measurement involves assessing the strength of a magnet’s magnetic field at a given distance from its surface. Coercivity testing evaluates a magnet’s resistance to demagnetization under external influences. Thermal stability assessments determine how well a magnet retains its magnetic properties under varying temperature conditions.

By implementing rigorous quality control protocols throughout the manufacturing process, manufacturers can ensure that their products meet stringent performance criteria.

Future Trends in Permanent Magnet Manufacturing

The future of permanent magnet manufacturing is poised for significant transformation as industries continue to seek innovative solutions that align with sustainability goals and technological advancements. One emerging trend is the exploration of alternative materials that reduce reliance on rare-earth elements while maintaining or enhancing magnetic performance. Researchers are actively investigating new alloys and composite materials that offer comparable properties without the environmental impact associated with traditional sources.

Additionally, advancements in automation and digitalization are set to revolutionize manufacturing processes further. The integration of artificial intelligence (AI) and machine learning algorithms into production lines will enable real-time monitoring and optimization of manufacturing parameters, leading to increased efficiency and reduced waste. As industries embrace these trends, permanent magnet manufacturing will evolve into a more sustainable and technologically advanced sector capable of meeting future demands effectively.

In conclusion, permanent magnet manufacturing encompasses a diverse array of techniques ranging from traditional methods to cutting-edge innovations. As industries continue to evolve, so too will the approaches used to produce these essential components. By addressing existing challenges and embracing new technologies, manufacturers can ensure that they remain at the forefront of this dynamic field while contributing to a more sustainable future.

In the field of permanent magnet manufacturing, understanding the latest advancements and techniques is crucial for industry professionals. A related article that delves into innovative methods and applications in this area can be found at My GeoQuest. This resource provides valuable insights that can enhance the knowledge and practices of those involved in the production and utilization of permanent magnets.

WATCH THIS! 🚨 THEY CONTROL 94% OF YOUR MAGNETS 🧲 — And You Never Noticed 🤫

FAQs

What are permanent magnets?

Permanent magnets are materials that produce a persistent magnetic field without the need for an external power source. They retain their magnetic properties over time.

What materials are commonly used in permanent magnet manufacturing?

Common materials include neodymium-iron-boron (NdFeB), samarium-cobalt (SmCo), alnico, and ferrite. Each material offers different magnetic strengths and temperature resistances.

What are the main methods used to manufacture permanent magnets?

Permanent magnets are typically manufactured using powder metallurgy processes such as sintering and bonding. Sintering involves pressing and heating powdered materials, while bonding uses adhesives to hold magnetic powders together.

What is the sintering process in permanent magnet manufacturing?

Sintering involves compacting magnetic powder into a desired shape and then heating it below its melting point to fuse the particles together, resulting in a dense and strong magnet.

How are bonded magnets different from sintered magnets?

Bonded magnets are made by mixing magnetic powders with a binder and then shaping them through injection molding or extrusion. They generally have lower magnetic strength but offer more design flexibility compared to sintered magnets.

What quality control measures are important in permanent magnet manufacturing?

Quality control includes checking magnetic properties like coercivity and remanence, dimensional accuracy, surface finish, and ensuring the absence of defects such as cracks or voids.

What applications use permanent magnets?

Permanent magnets are used in electric motors, generators, sensors, magnetic resonance imaging (MRI), loudspeakers, and various electronic devices.

How does temperature affect permanent magnets?

High temperatures can reduce the magnetic strength and cause irreversible demagnetization. Different magnet materials have varying maximum operating temperatures.

Are permanent magnets recyclable?

Yes, permanent magnets can be recycled by recovering the magnetic materials, which helps reduce environmental impact and conserve raw materials.

What advancements are being made in permanent magnet manufacturing?

Advancements include developing magnets with higher magnetic strength, improved temperature stability, and using environmentally friendly materials and manufacturing processes.