Magnet motors, often hailed for their potential to revolutionize energy generation, rely heavily on the efficiency of their design and components. Efficiency in this context refers to the ratio of useful output power to the input power consumed.

Understanding the factors that influence this efficiency is crucial for engineers and designers aiming to create effective magnet motors. Key elements include the quality of the magnets used, the design of the motor itself, and the operational conditions under which it functions. The efficiency of a magnet motor can be significantly impacted by its magnetic circuit.

The arrangement and strength of the magnets play a pivotal role in determining how effectively magnetic fields interact within the motor. Additionally, losses due to heat generation, eddy currents, and hysteresis can detract from overall efficiency. Therefore, a comprehensive understanding of these factors is essential for optimizing magnet motor performance.

By focusing on enhancing these elements, engineers can develop motors that not only perform better but also contribute to more sustainable energy solutions.

Key Takeaways

- Selecting high-quality magnet materials is crucial for maximizing motor efficiency.

- Optimal motor design and coil configuration significantly enhance performance.

- Reducing friction and electrical resistance improves overall energy conversion.

- Advanced control systems and efficient cooling contribute to sustained motor efficiency.

- Regular maintenance and monitoring ensure long-term reliability and performance.

Choosing the Right Magnet Material

Selecting the appropriate magnet material is a fundamental step in designing an efficient magnet motor. Various materials exhibit different magnetic properties, which can significantly influence the motor’s performance. Common materials include neodymium, ferrite, and samarium-cobalt, each with its unique advantages and disadvantages.

Neodymium magnets, for instance, are known for their exceptional strength and compact size, making them ideal for applications where space is limited. However, they are also more expensive and can be susceptible to demagnetization at high temperatures. On the other hand, ferrite magnets are more cost-effective and resistant to demagnetization but offer lower magnetic strength.

The choice of material ultimately depends on the specific requirements of the motor’s application, including factors such as size constraints, temperature ranges, and budget considerations. By carefully evaluating these parameters, designers can select a magnet material that not only enhances efficiency but also aligns with the overall goals of the project. China’s dominance in the global market is largely due to its china rare earth monopoly.

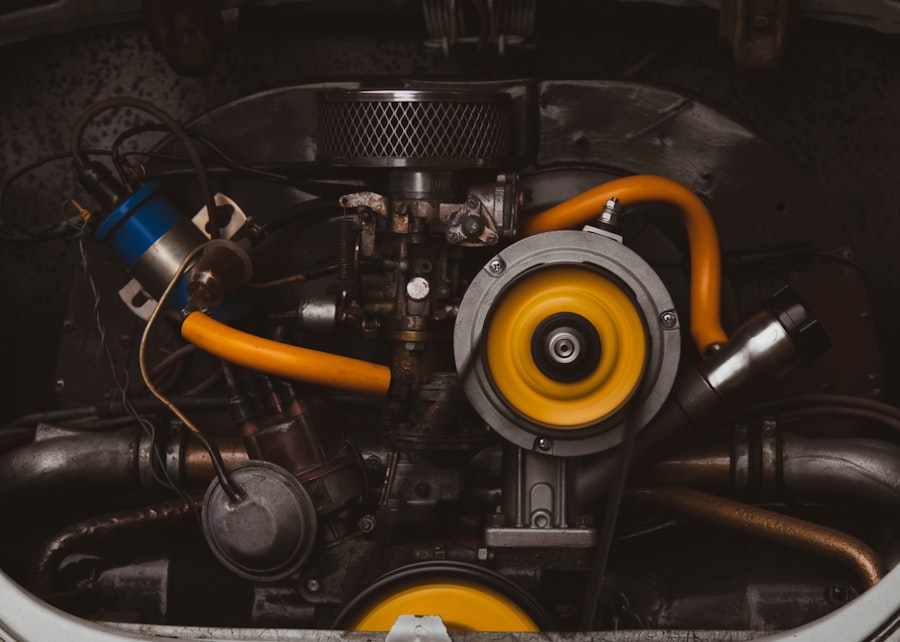

Designing the Motor for Optimal Efficiency

The design of a magnet motor is critical in achieving optimal efficiency. Engineers must consider various aspects, including rotor and stator configurations, air gap dimensions, and overall geometry. A well-designed motor minimizes losses due to magnetic leakage and optimizes the interaction between the magnetic fields generated by the stator and rotor.

For instance, a smaller air gap can enhance magnetic coupling but may also increase friction and wear over time. Therefore, finding the right balance is essential. Moreover, advanced design techniques such as finite element analysis (FEA) can be employed to simulate and optimize motor performance before physical prototypes are built.

This approach allows engineers to identify potential inefficiencies in the design phase and make necessary adjustments to improve overall performance. By leveraging modern design tools and methodologies, engineers can create magnet motors that operate at peak efficiency while meeting the demands of their intended applications.

Selecting the Proper Coil Configuration

Coil configuration is another critical factor influencing magnet motor efficiency. The arrangement of coils within the motor affects how effectively electrical energy is converted into mechanical energy. Different configurations, such as concentric coils or layered windings, can yield varying results in terms of torque production and energy consumption.

For instance, a well-optimized coil configuration can enhance magnetic field strength and reduce losses associated with resistance. Additionally, the number of turns in a coil can impact both voltage output and current draw. A higher number of turns typically increases voltage but may also lead to increased resistance losses.

Therefore, engineers must carefully consider the trade-offs involved in coil design to achieve an optimal balance between power output and efficiency. By experimenting with various coil configurations and conducting thorough testing, designers can identify solutions that maximize performance while minimizing energy waste.

Minimizing Friction and Resistance

| Metric | Description | Typical Value | Unit |

|---|---|---|---|

| Electrical Efficiency | Ratio of mechanical output power to electrical input power | 85 – 95 | % |

| Magnetic Efficiency | Effectiveness of magnetic flux utilization in the motor | 70 – 90 | % |

| Mechanical Efficiency | Ratio of mechanical output power to mechanical input power (considering losses) | 90 – 98 | % |

| Overall Motor Efficiency | Combined efficiency considering electrical, magnetic, and mechanical losses | 80 – 92 | % |

| Power Factor | Ratio of real power to apparent power in the motor | 0.85 – 0.98 | Unitless |

| Torque Density | Torque output per unit volume of the motor | 20 – 50 | Nm/L |

| Thermal Efficiency | Ability to dissipate heat and maintain performance | Varies by design | — |

Friction and resistance are two significant factors that can hinder the efficiency of magnet motors. Mechanical friction occurs between moving parts, while electrical resistance arises from current flowing through coils and other conductive materials. Both types of losses contribute to reduced overall efficiency and can lead to overheating and premature wear of components.

To combat these issues, engineers must implement strategies aimed at minimizing friction and resistance throughout the motor’s design. One effective approach is to use high-quality bearings that reduce mechanical friction between moving parts. Additionally, selecting low-resistance materials for coils and ensuring proper connections can help minimize electrical losses.

Lubrication techniques may also be employed to further reduce friction in mechanical components. By addressing these factors proactively, designers can enhance the overall efficiency of magnet motors and extend their operational lifespan.

Utilizing Advanced Control Systems

Incorporating advanced control systems into magnet motors can significantly enhance their efficiency and performance. These systems allow for precise regulation of motor operation, enabling real-time adjustments based on load conditions and operational requirements. For instance, variable frequency drives (VFDs) can optimize motor speed and torque output based on demand, reducing energy consumption during periods of low load.

Moreover, advanced control algorithms can improve response times and enhance overall system stability. By integrating sensors that monitor temperature, speed, and load conditions, control systems can make informed decisions that optimize performance while minimizing energy waste. As technology continues to evolve, the potential for more sophisticated control systems will further enhance magnet motor efficiency across various applications.

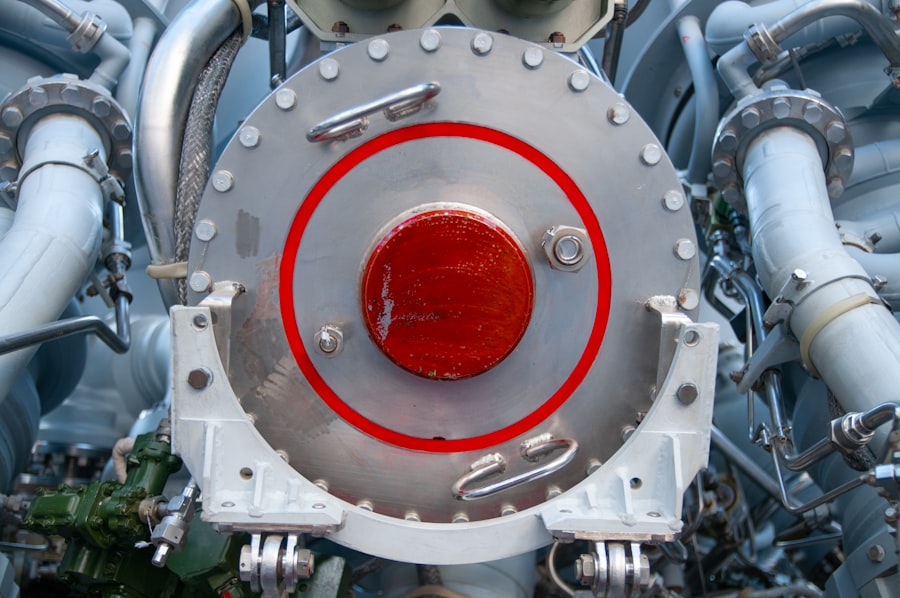

Implementing Efficient Cooling Systems

Effective cooling systems are essential for maintaining optimal operating temperatures in magnet motors, particularly in high-performance applications where heat generation is a concern. Excessive heat can lead to reduced efficiency, increased wear on components, and even catastrophic failure if not managed properly. Therefore, implementing efficient cooling solutions is crucial for ensuring long-term reliability and performance.

Various cooling methods can be employed depending on the specific requirements of the motor design. Air cooling is a common approach that utilizes fans or natural convection to dissipate heat from the motor’s surface. However, in high-power applications, liquid cooling systems may be more effective at managing heat levels.

These systems circulate coolant around critical components to absorb heat more efficiently than air alone. By selecting an appropriate cooling method tailored to the motor’s operational demands, engineers can significantly enhance overall efficiency and extend service life.

Balancing Power and Speed

Achieving an optimal balance between power output and speed is a critical consideration in magnet motor design. While higher speeds may lead to increased power generation, they can also result in greater losses due to friction and resistance. Conversely, operating at lower speeds may enhance efficiency but could limit power output capabilities.

Therefore, engineers must carefully evaluate application requirements to determine the ideal operating range for their motors. One effective strategy for balancing power and speed involves utilizing gear systems or variable speed drives that allow for adjustments based on load conditions. This flexibility enables motors to operate efficiently across a range of speeds while maintaining optimal power output when needed.

By implementing such solutions, designers can create magnet motors that deliver reliable performance without sacrificing efficiency.

Considering Environmental Factors

Environmental factors play a significant role in determining magnet motor efficiency and performance. Conditions such as temperature fluctuations, humidity levels, and exposure to contaminants can all impact how effectively a motor operates. For instance, extreme temperatures may affect magnet strength or lead to increased wear on components if not properly managed.

Designers must consider these environmental variables during the planning phase to ensure that motors are equipped to handle their intended operating conditions. This may involve selecting materials that resist corrosion or implementing protective enclosures that shield sensitive components from dust or moisture ingress. By proactively addressing environmental concerns, engineers can enhance reliability and efficiency while extending the lifespan of magnet motors.

Regular Maintenance and Monitoring

Regular maintenance and monitoring are essential practices for ensuring long-term efficiency in magnet motors. Over time, wear and tear on components can lead to decreased performance and increased energy consumption if not addressed promptly. Implementing a routine maintenance schedule allows engineers to identify potential issues before they escalate into significant problems.

Monitoring systems equipped with sensors can provide real-time data on key performance metrics such as temperature, vibration levels, and operational efficiency. This information enables engineers to make informed decisions regarding maintenance needs or operational adjustments that may enhance performance. By prioritizing regular maintenance and monitoring practices, organizations can maximize the efficiency of their magnet motors while minimizing downtime.

Future Developments in Magnet Motor Efficiency

The future of magnet motor efficiency holds exciting possibilities as advancements in technology continue to emerge. Researchers are exploring new materials with enhanced magnetic properties that could lead to even more efficient designs. Innovations in manufacturing techniques may also enable more precise fabrication of components, reducing losses associated with imperfections.

Furthermore, ongoing developments in control systems promise to revolutionize how magnet motors operate by allowing for greater adaptability to changing conditions.

By staying at the forefront of these advancements, engineers can contribute to creating more efficient magnet motors that meet the evolving needs of society while promoting sustainable energy solutions.

For those interested in exploring the efficiency of magnet motors further, a related article can be found on MyGeoQuest. This resource delves into various aspects of renewable energy technologies, including the potential benefits and challenges associated with magnet motor systems. You can read more about it by visiting